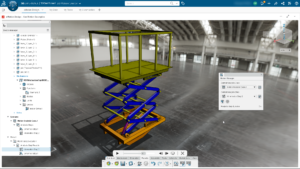

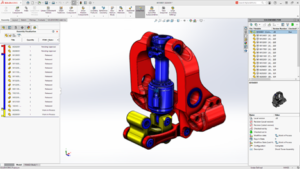

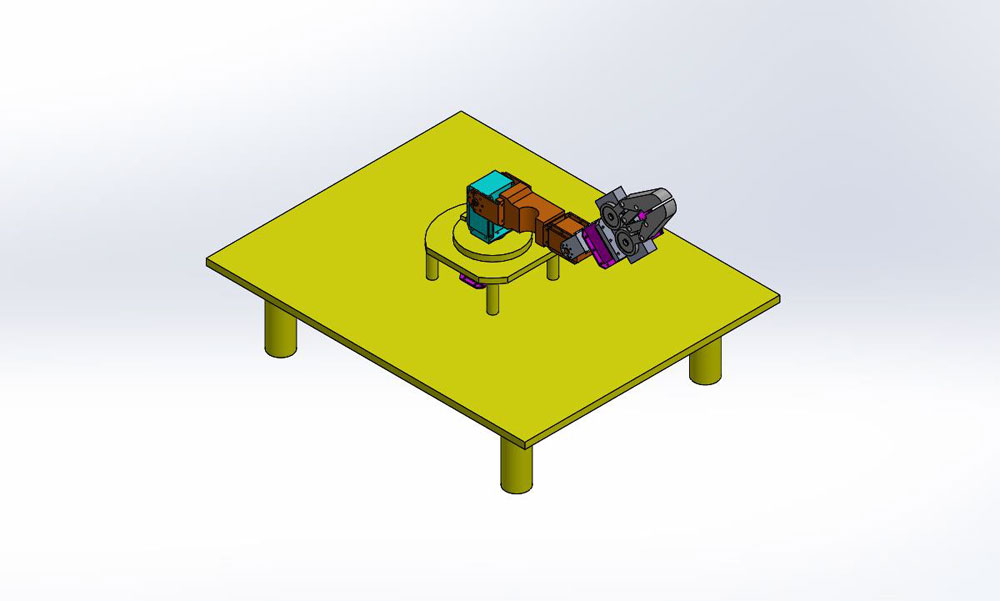

Subassemblies are an excellent method for both organizing design assets and improving assembly performance in SOLIDWORKS. Simply put, a subassembly is an assembly within an assembly, and they’re used very regularly by design professionals. But what happens when motion is required in a subassembly? If you’ve ever worked with subassemblies, you’ve likely found that by default, subassemblies do not allow for motion between their respective components, and can only move as a group (this improves system performance as SOLIDWORKS is required to perform fewer calculations). Fortunately, this is fixed in only a couple clicks by making the subassembly flexible, as I’ll demonstrate using the robotic arm assembly shown below:

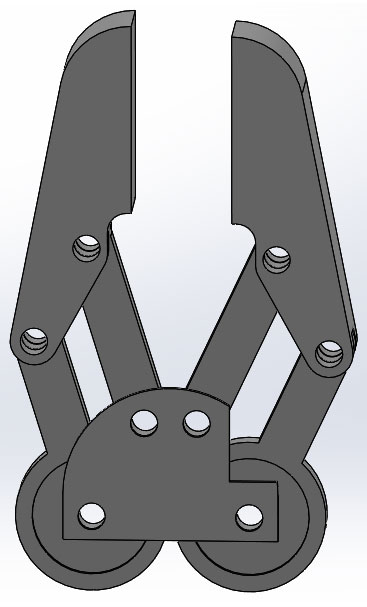

The goal for this assembly is to make the sub-assembly X3 movable so that it should pick an object. And this requires movement of the claw and segment 4&5 as shown below:

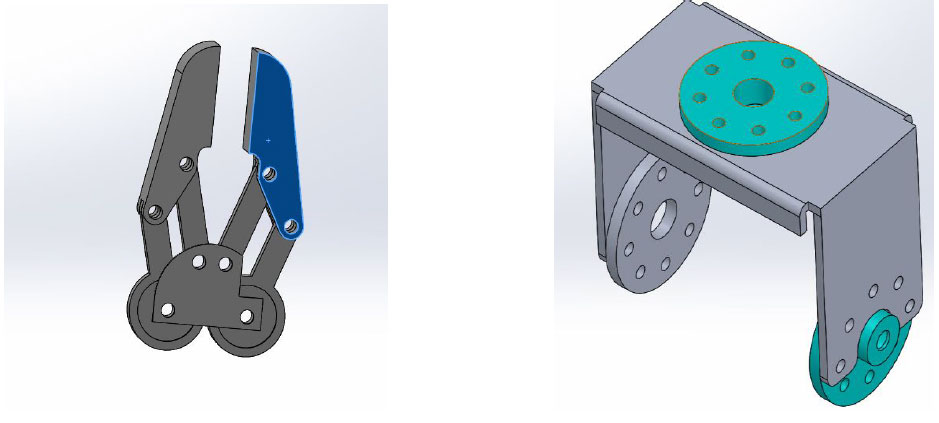

When inserting a subassembly, SOLIDWORKS uses the position that the sub-assembly was last saved in (or current position, if the subassembly is open). In this case, the claw is open, and once mated, it cannot move from the position shown below:

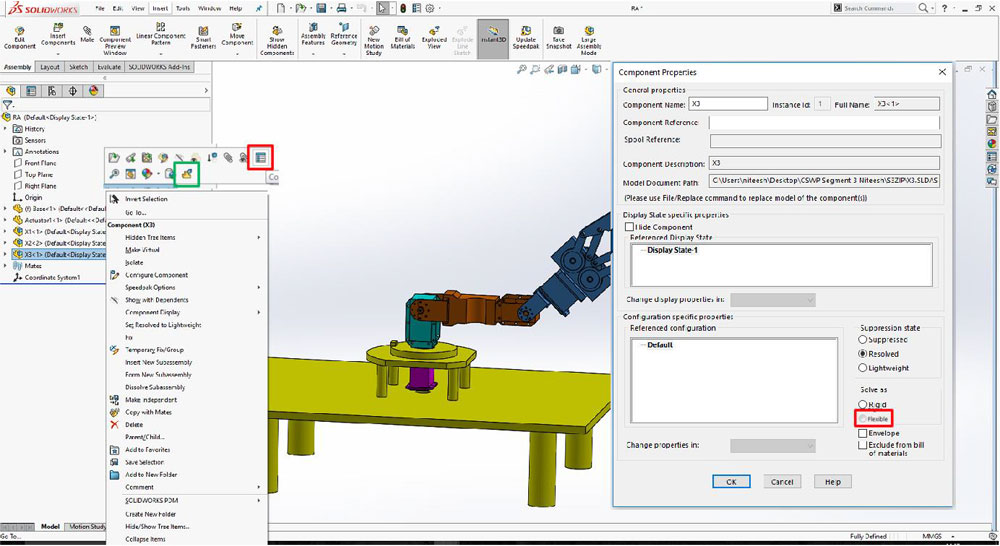

In order to show the subassembly motion in all its glory, simply right click the subassembly in the Feature Manager Design Tree and choose Component Properties from the context menu. From here, under Solve As, select Flexible. You should also have a shortcut icon in the context menu (shown below in green) to make the subassembly flexible directly.

That’s all there is to it! The subassembly will now have full motion available as per our requirement, and the options from here are endless. However flexible subassemblies have the potential to slow down system performance significantly, especially for large subassemblies with many moving components, and should be used with discretion. Additionally, subassemblies must be resolved in order to make them flexible (lightweight mode cannot be used).