3DEXPERIENCE SIMULATION

3DEXPERIENCE Works - Simulation

Accelerate the process of evaluating the performance, reliability and safety of materials and products before committing to physical prototypes.

An integrated suite of simulation tools that accelerate the process of evaluating and improving product performance, reliability and safety before committing to costly and time-consuming physical prototypes. With market-leading simulation applications our customers can meet their business goals of reduced cost and time to market while delivering innovative products.

Structure

A comprehensive set of structural analysis solutions to guide design decisions and improve product performance and quality.

Computational Fluid Dynamics

Perform fluid flow and heat transfer simulations to improve quality and avoid product performance issues.

Plastic Injection

Validate and optimize injection molded part designs early in the product development process.

Electromagnetics

Bridge the gap between your design and manufacturing processes

Simulation Review

Facilitate collaborative decision making across the organization through the 3DDashboard to review, compare, and perform trade-offs between design alternatives.

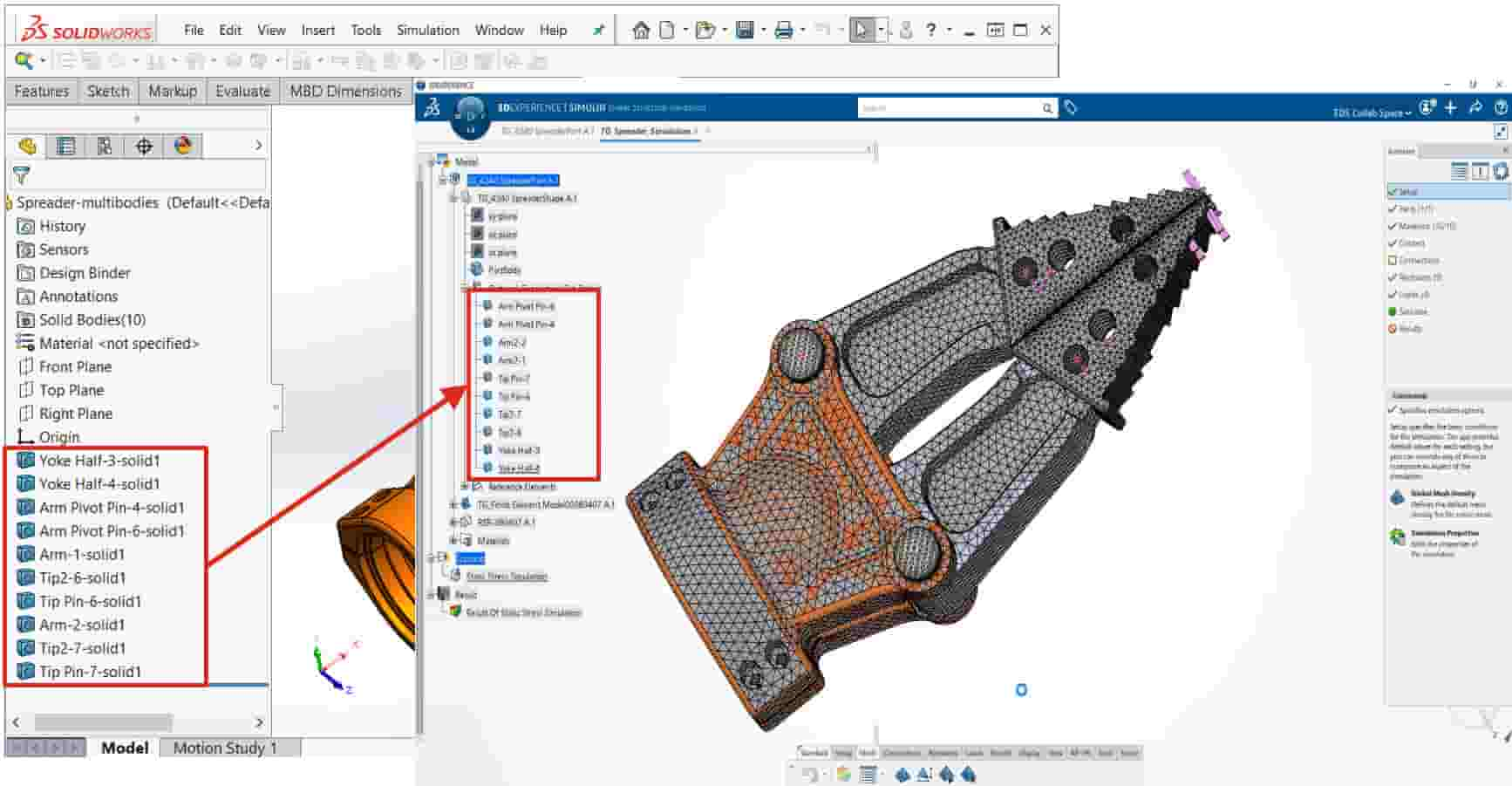

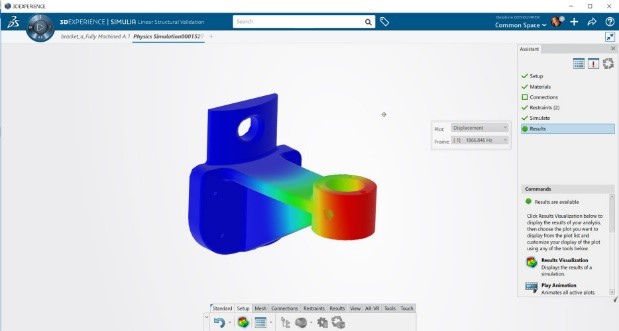

STRUCTURE

A comprehensive set of structural analysis solutions to guide design decisions and improve product performance and quality.

Structures analysis covers linear and nonlinear static, dynamic, and thermal simulation of solids and structures using Finite Element Methods.

It provides unique capabilities to collaborate, simulate, and impact product development processes throughout the extended enterprise using state-of-the-art Abaqus simulation technology, ensuring accuracy of the virtual testing.

On the 3DEXPERIENCE platform, simulation methods can be defined, stored, replayed, and maintained allowing customers to develop and centralize on their own best-practices to increase quality, reliability, and efficiency of structural validation.

It provides unique capabilities to collaborate, simulate, and impact product development processes throughout the extended enterprise using state-of-the-art Abaqus simulation technology, ensuring accuracy of the virtual testing.

On the 3DEXPERIENCE platform, simulation methods can be defined, stored, replayed, and maintained allowing customers to develop and centralize on their own best-practices to increase quality, reliability, and efficiency of structural validation.

Structural Designer

An intuitive Design Simulation solution for Designers looking for efficient product performance assessment under linear static conditions to guide the design process.

Structural Designer is a role developed with designers in mind. Design process is made of multiple iterations, multiple what if ideas to successfully deliver the right product to manufacturing.Structural Designer delivers linear static, natural frequency, buckling and steady-state thermal simulation capabilities for fast and efficient product testing experience.

Structural Engineer

An intuitive Design Simulation role for Design Engineers providing comprehensive linear structural analysis solution to assess the performance of products during the product development process.

Structural Engineer equips the Design Engineer with all the tools needed to efficiently conduct structural linear static, frequency, buckling, steady-state thermal simulation and modal dynamic response of product designs within 3DEXPERIENCE.

Structural Engineer includes modal dynamic response simulation capability. Vibration behavior can be simulated to avoid resonance problems by knowing natural frequencies and avoid critical flaws on product behavior.

Structural Engineer includes modal dynamic response simulation capability. Vibration behavior can be simulated to avoid resonance problems by knowing natural frequencies and avoid critical flaws on product behavior.

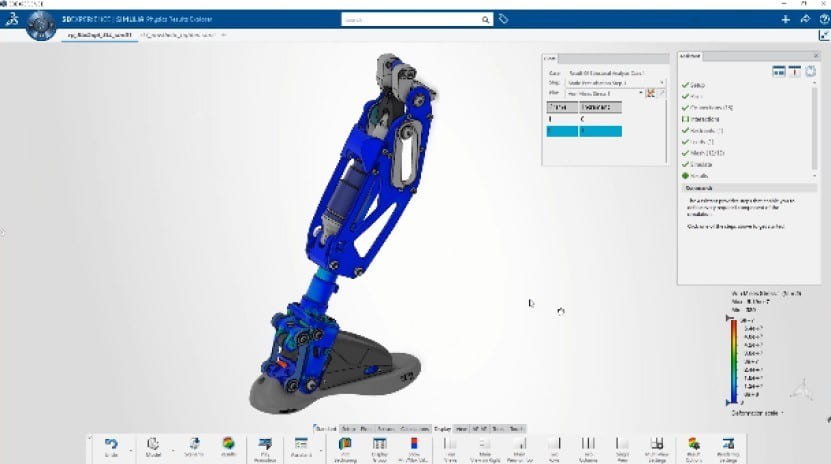

Structural Performance Engineer

Assess the structural performance of products during the Design process and intuitively guide design decisions.

Structural Performance Engineer enables product engineers to conduct structural linear and nonlinear static, frequency, buckling, modal dynamic response, and structural thermal simulation of parts and assemblies on the cloud-based 3DEXPERIENCE platform.

Structural Performance Engineer boosts innovation in product engineering and foster collaboration through fast, realistic and accurate simulation with Abaqus technology, leader in the structural analysis industry.

Structural Performance Engineer boosts innovation in product engineering and foster collaboration through fast, realistic and accurate simulation with Abaqus technology, leader in the structural analysis industry.

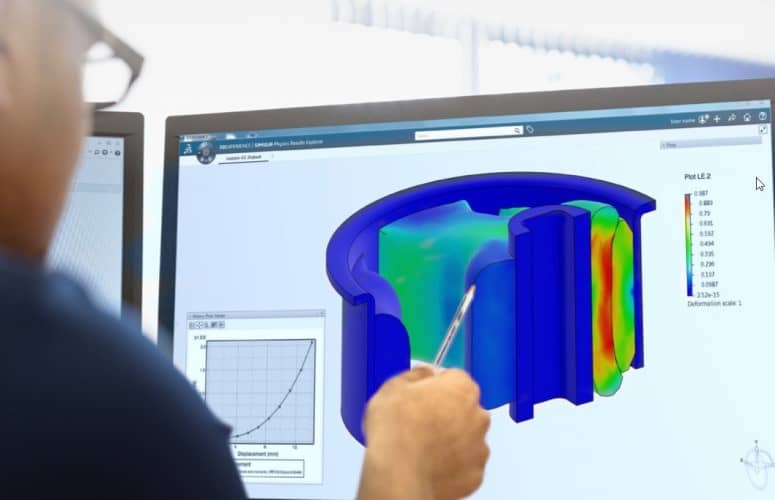

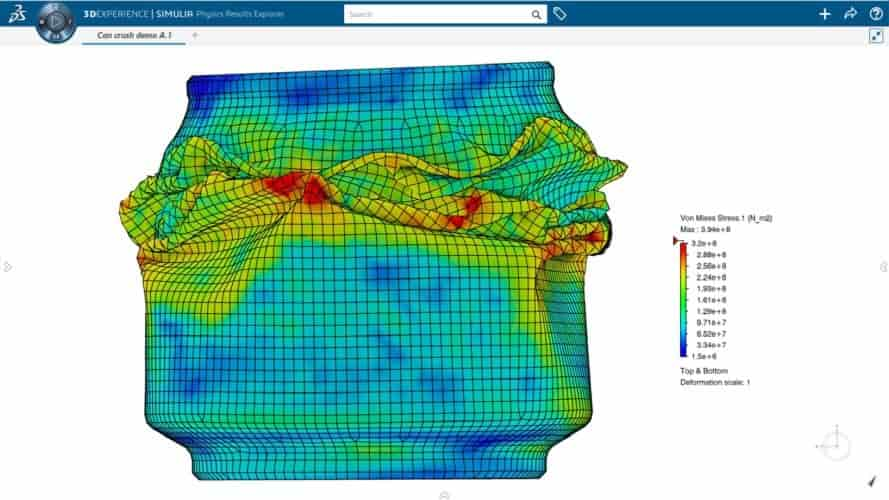

Structural Mechanics Engineer

Enables comprehensive structural simulations covering statics, implicit and explicit dynamics, acoustics across a broad range of industrial applications.

Structural Mechanics Engineer is a comprehensive role to perform structural integrity assessment of any type of product, providing:

- Structural analysis (static or quasi-static, frequency, buckling, mode-based steady-state or transient dynamic, random response, non-linear dynamic)

- Thermal analysis or sequential thermal-stress analyses (both transient or steady state)

- Axisymmetric idealization for fast structural analysis, especially useful in a preliminary design context to determine trends

- Advanced capability from modeling and meshing, with possible automated creation (e.g.mid-surfacing), scenario definition, execution, results visualization, and report generation

- Embedded tokens for running the analyse

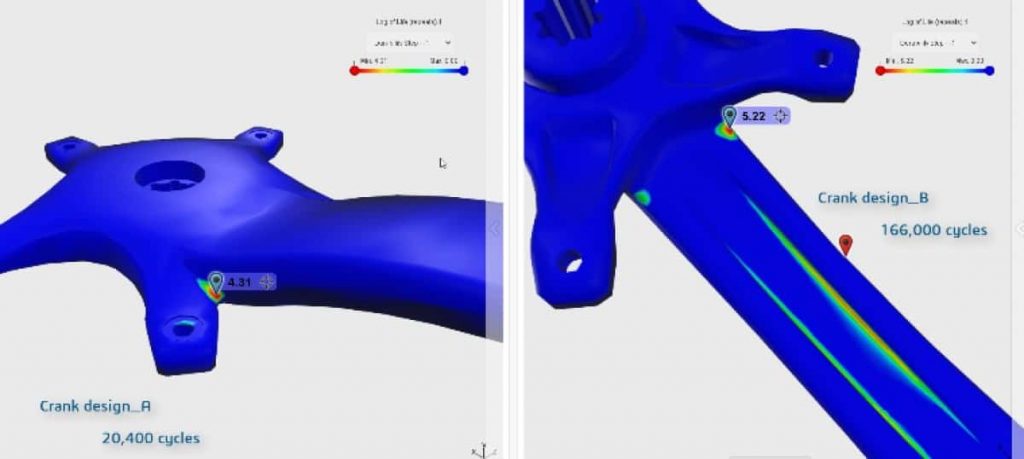

Durability Performance Engineer

Assess the structural performance and durability of products during the design process and intuitively guide design decisions.

Durability Performance Engineer enables design engineers to assess the structural performance and durability of products during the Design process and intuitively guide design decisions. It offers powerful and intuitive tools needed to perform sophisticated multistep structural simulations, powered by market leader Abaqus technology, as well as fatigue simulation to predict accurate fatigue lives.

Durability and Mechanics Engineer

Enables comprehensive structural simulations covering statics, implicit and explicit dynamics, durability and fatigue to perform structural integrity assessment of any type of product.

Durability & Mechanics Engineer Enables Design engineers to perform structural integrity assessment of any type of product for strength and durability scenarios during the Design process and intuitively guide design decisions. It offers powerful and intuitive tools needed to perform sophisticated multistep structural simulations, powered by market leader Abaqus technology, as well as fatigue simulation to predict accurate fatigue lives

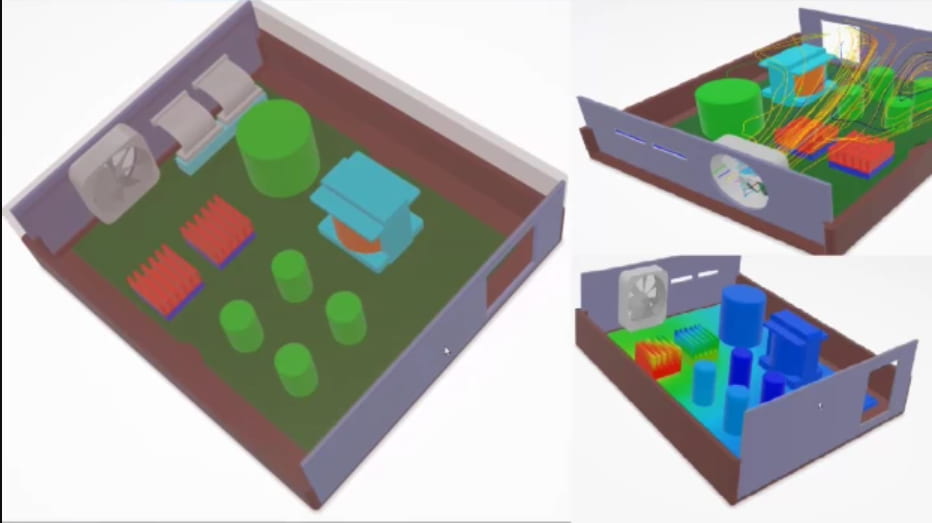

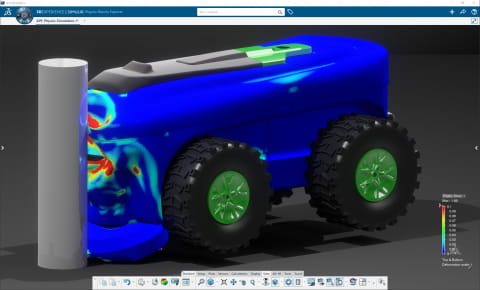

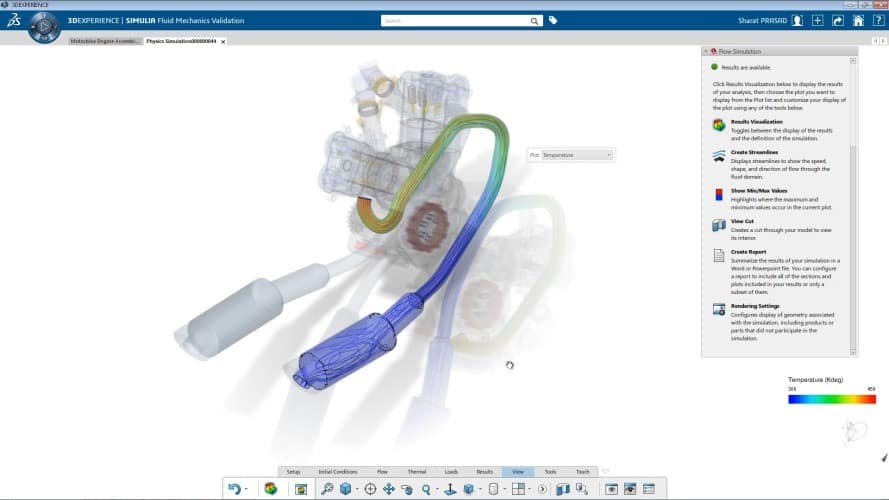

COMPUTATIONAL FLUID DYNAMICS

Perform fluid flow and heat transfer simulations to improve quality and avoid product performance issues.

Computational Fluid Dynamics (CFD) covers steady-state and transient flow analysis around and through solids and structures. A fully-featured Navier-Stokes solver is provided. Internal and external fluid domain models can be developed from solids and structures allowing flow and thermal analysis including model building directly on the design geometry. A complete complement of fluid meshing tools, multi-step scenario definition, solution, and results post-processing and reporting tools is provided allowing customers to increase quality, reliability, and efficiency of designs requiring fluid validation.

Fluid Dynamics Engineer

A Simulation Role for Engineers who perform routine fluid flow and thermal calculations to guide design modifications and explore innovative design concepts.

Fluid Dynamics Engineer provides designers and design engineers with the ability to validate fluid and thermal performance for internal/ external flows and conjugate heat transfer problems. With a CAD-enabled CFD approach, Fluid Dynamics Engineer enables users to quickly explore 100s of designs while concurrently improving product performance based on optimal flow distribution, efficient thermal management, minimal pressure losses etc. Fluid Dynamics Engineer leverages industry standard RANS based finite volume Computational Fluid Dynamics (CFD) technology with an integrated (CAD+CFD+PLM) and fully guided user experience tailored for Designers to perform end-to-end product design efficiently on a single collaborative environment of 3DEXPERIENCE Platform.

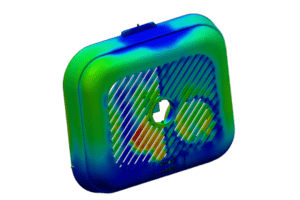

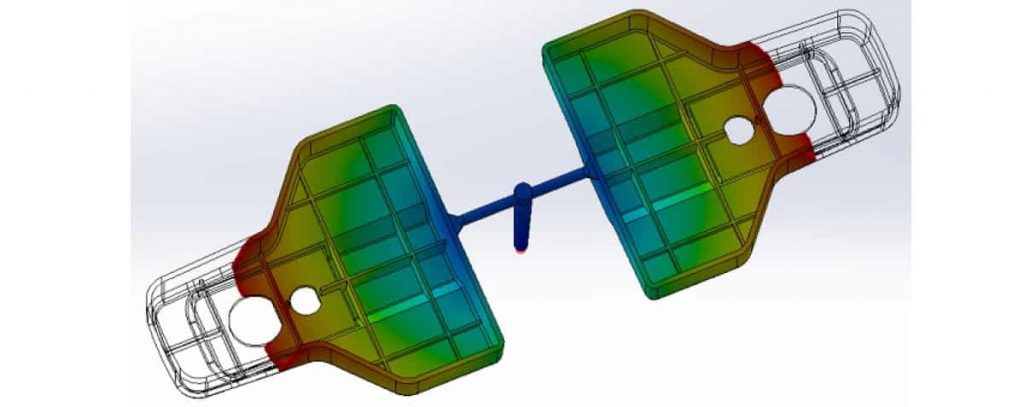

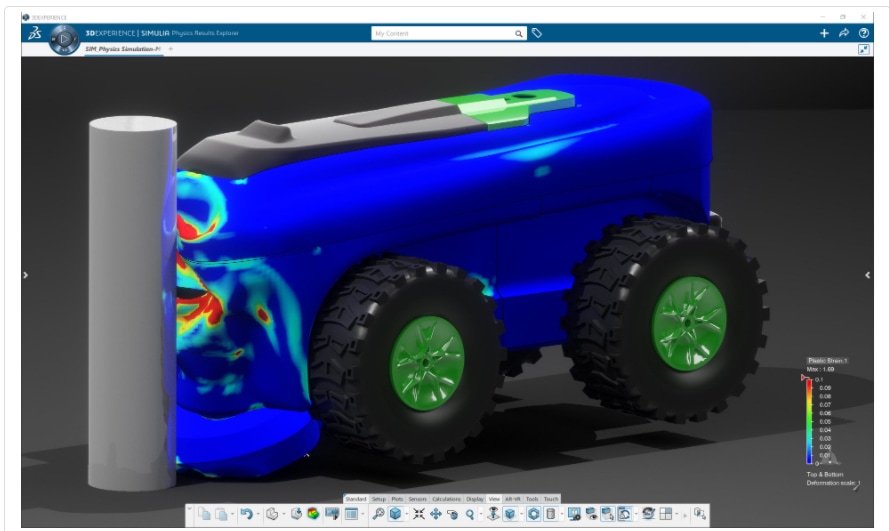

PLASTIC INJECTION

Validate and optimize injection molded part designs early in the product development process.

Plastic Injection brings easy-to-use injection molding simulation directly to the designers of plastic parts and injection molds.

Plastic Injection Engineer

Plastic Injection Engineer enables the validation and optimization of plastic part and mold tooling designs by simulating the filling, packing, warpage & mold cooling early in the product development process.

It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects on plastic parts. You can quickly evaluate manufacturability while you design, to eliminate costly part redesign, improve part quality, and accelerate time to market. Plastic part designers and product developers can analyze and modify designs at the same time as optimizing for form, fit, and function, by simulating the filling, packing, warpage & mold cooling early in the product development process. Mold tool designers can evaluate and optimize the feed system and cooling circuit designs.

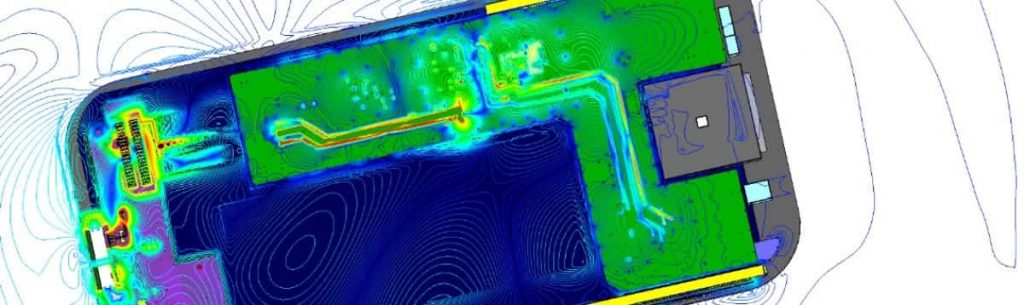

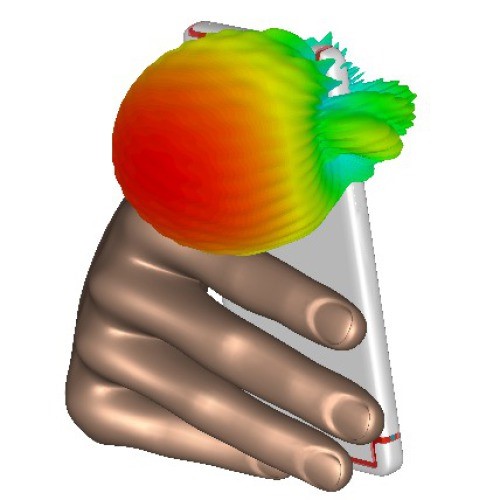

ELECTROMAGNETICS

A comprehensive set of electromagnetic analysis solutions to guide design decisions and improve product performance and quality.

Electromagnetic components are crucial to the success of an increasing range of products in our smart, connected and sustainable world, as well as the emerging markets such as medical equipment, renewable energy and metamaterials. Even long-established industries such as automotive and communications are being disrupted by new electrical and electronic devices that require electromagnetic simulation to ensure product performance and regulatory compliance. Designers and engineers need to perform electromagnetic simulations from low to high frequency, including optimization of antennas and microwave components as well as electro-mechanical devices, to validate performance, reduce the time-to-market and to avoid device malfunctions, warranty claims and recalls.

Electromagnetics Engineer

Delivering high-performance 3D Electromagnetic simulation for analyzing and optimizing Electromagnetic components and systems on the 3DEXPERIENCE platform.

The SIMULIA Electromagnetics Engineer role delivers electromagnetic simulation powered by

industry proven CST Studio Suite technology in a seamless, intuitive, and modern user interface

connected with the 3DEXPERIENCE platform.

It enables designers and engineers to perform electromagnetic simulations from low to high frequency (static to optical), including the optimization of antennas, microwave components and electro-mechanical devices. SIMULIA Electromagnetics Engineer enables design teams to improve product performance, reduce time-to-market and minimize device malfunctions, warranty claims and recalls.

SIMULIA Electromagnetics Engineer offers a broad range of solution methods with a unique capability to identify and mitigate electromagnetic compatibility (EMC) and electromagnetic interference (EMI) risks in electronic devices. Additionally, the technology can be applied to simulation of human body exposure to electromagnetic fields. Electromagnetic Engineer ensures that the device passes any certification tests required by regulatory and industry standards first time.

It enables designers and engineers to perform electromagnetic simulations from low to high frequency (static to optical), including the optimization of antennas, microwave components and electro-mechanical devices. SIMULIA Electromagnetics Engineer enables design teams to improve product performance, reduce time-to-market and minimize device malfunctions, warranty claims and recalls.

SIMULIA Electromagnetics Engineer offers a broad range of solution methods with a unique capability to identify and mitigate electromagnetic compatibility (EMC) and electromagnetic interference (EMI) risks in electronic devices. Additionally, the technology can be applied to simulation of human body exposure to electromagnetic fields. Electromagnetic Engineer ensures that the device passes any certification tests required by regulatory and industry standards first time.

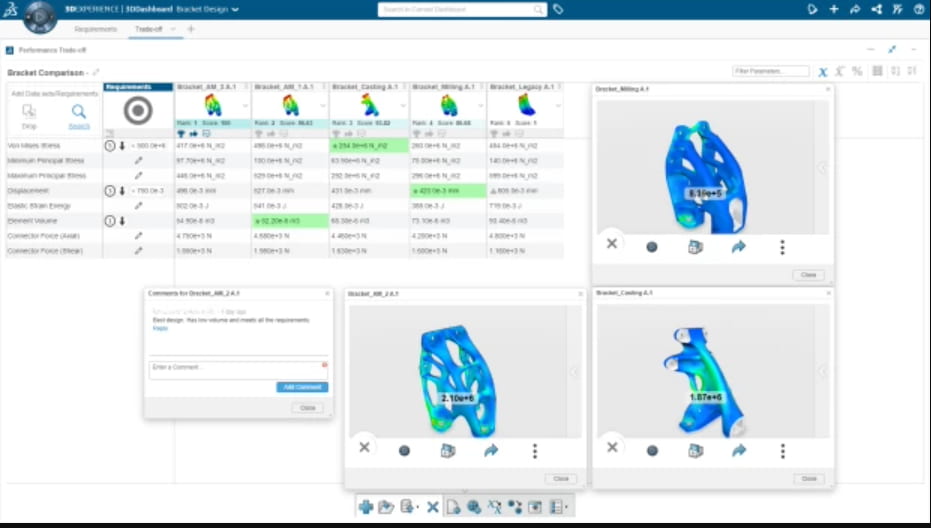

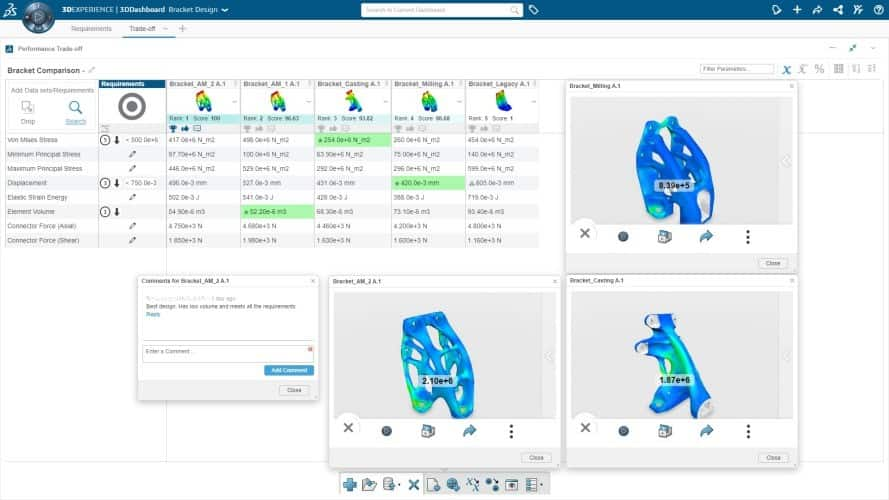

SIMULATION REVIEW

Facilitate collaborative decision making across the organization through the 3DDashboard to review, compare, and perform trade-offs between design alternatives.

Simulation Review delivers detailed information to engineers and design teams enabling them to make value-based trade-off decisions between product design alternatives.

Simulation Collaborator

Simulation Collaborator delivers easy to use tools on the 3DEXPERIENCE platform enabling seamless engineering collaboration between any project stakeholder to make well informed, traceable and data-driven decisions.

SIMULIA Simulation Collaborator role facilitates collaborative decision making across an organization through 3DDashboard access to review, compare and preform trade-offs between design alternatives. Engineers can share simulation data with stakeholders enabling them to visualize & compare different design choices on their 3DDashboard. Cross-functional teams can work concurrently to provide their perspective on divergent goals and understand the implications and consequences of trade-offs – thereby reacting to changes to gain alignment and agreement through real-time informed discussions.

Related Blogs

Document Management System made easy with 3DEXPERIENCE Platform

Surendiran R

December 2, 2021

Document management is a system or process used to capture, track

SIMULIAworks in 3DEXPERIENCE Platform

Mahendra K H

March 8, 2021

Validating your design with virtual Simulation software require powerful and