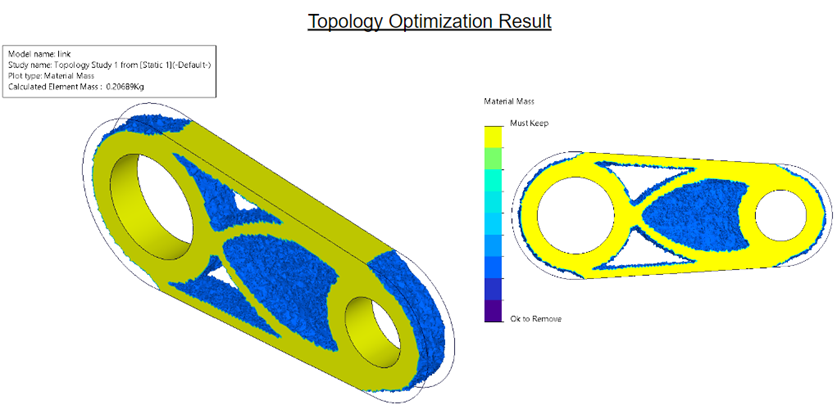

SOLIDWORKS Topology Optimization – Develop products with Maximum strength and Minimum Weight

Every organization focused towards reducing the cost of their traditional

SOLIDWORKS Simulation Linear Stress Analysis enables engineers to calculate stresses and deformations due to internal and external loads and validate the quality, performance, and safety of your design.

Using SOLIDWORKS Simulation Finite Element Analysis we can validate the performance and safety factors of the design.

Dynamic Analysis enables to determine the impact of dynamic loads and structural responses of the design.

SOLIDWORKS Simulation Vibration Analysis enables to determine design’s response to vibrations and gives Stresses, deformation, velocity, and acceleration as results.

SOLIDWORKS Simulation Non-Linear Analysis enables to calculate stresses and deforms under general loading and material conditions.

The designs which subjected to the dynamic environment, must gone through the SOLIDWORKS Simulation frequency analysis using dynamic design studies.

SOLIDWORKS Thermal Analysis helps to calculate temperatures and heat transfers between the components of the assembly.

Buckling Analysis to calculate the load factor at which a structure will lose its compressive stiffness and collapse, causing failure.

Every organization focused towards reducing the cost of their traditional

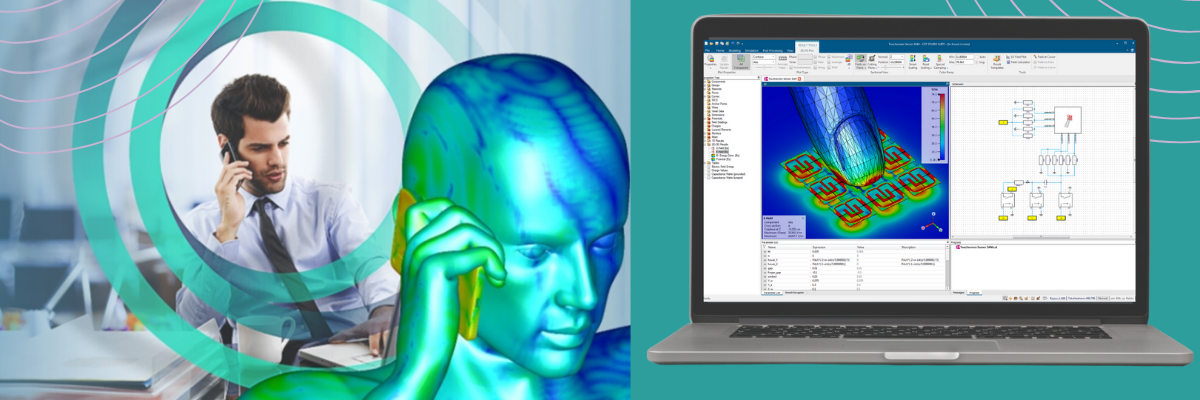

Electromagnetism and CST Simulation Have you ever thought about how

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

+91 9590506408