SOLIDWORKS is a versatile and easy-to-use CAD tool that provides various advantages when it comes to handling sheet metal design. Sheet Metal fabrication plays a crucial role in the manufacturing process for various industries due to its significance, such as creating complex parts quickly and efficiently without compromising strength & quality. It is a process of forming, cutting, and assembling components from sheet metal. The sheet metal components offer several benefits over traditional methods, including consistent finish quality, cost savings, and time efficiency. In this blog, we will discuss how SOLIDWORKS 3D CAD software will benefit the sheet metal industries in meeting their requirements and how it eases the manufacturing process.

General Challenges Facing in Sheet Metal Components Design

The flat pattern represents the unfolded sheet metal shape or fabrication shapes before forming processes like bending, rolling, etc. For fabricating a sheet metal flat pattern blank, 2D DXF/DWG files of final 3D components are required for CNC, laser cut, or punching operations. However, the following difficulties are involved in the design process to create these flat pattern bases from 3D sheet metal component designs.

- Design Intent communication

- Design & Manufacturing accuracy and precision

- Material & Bending constraints

- Time & Effort involved

- Fabrication challenges

- Adherence to design standard

These challenges can easily be overcome using SOLIDWORKS CAD solution. The Sheetmetal design features offer a systematic approach to crafting sheet metal parts, enabling users to define parameters like material thickness, bend radius, and corner relief. Additionally, it can automatically compute the component’s flat pattern, generating a 2D profile flat pattern instantly.

Benefits of SOLIDWORKS to Sheet Metal Design

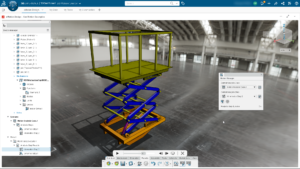

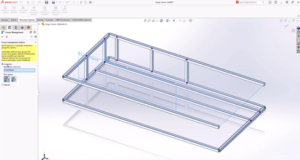

- SOLIDWORKS CADoffers a wide range of Sheet Metal features, including Edge Flange, Mitter Flange, Swept Flange, Loft Flange, Tab & Slot, Vent, and more (as per the below image) in a User-Friendly Interface. These features streamline the design process and enable users to create intricate product designs efficiently in less time. Additionally, the precision of the flattened profile aligns with real-time calculations, ultimately saving time and reducing effort.

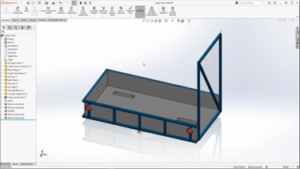

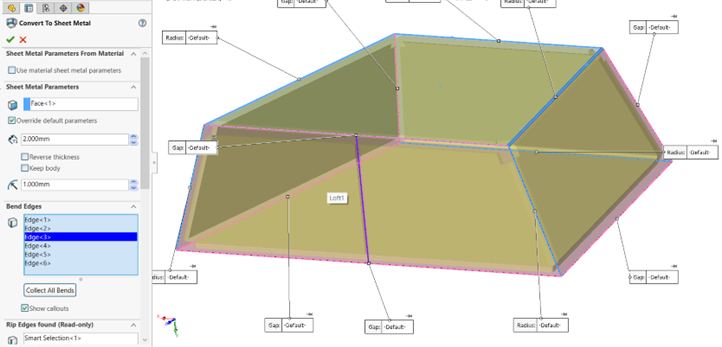

- If you are tasked with designing an enclosure for any neutral files like STEP, Parasolid, IGES, etc., utilizing the Convert to Sheet metal feature can help you achieve perfection and ease, as seen in the following image. This feature enhances the efficiency of the design process by eliminating the need to create the enclosure from scratch.

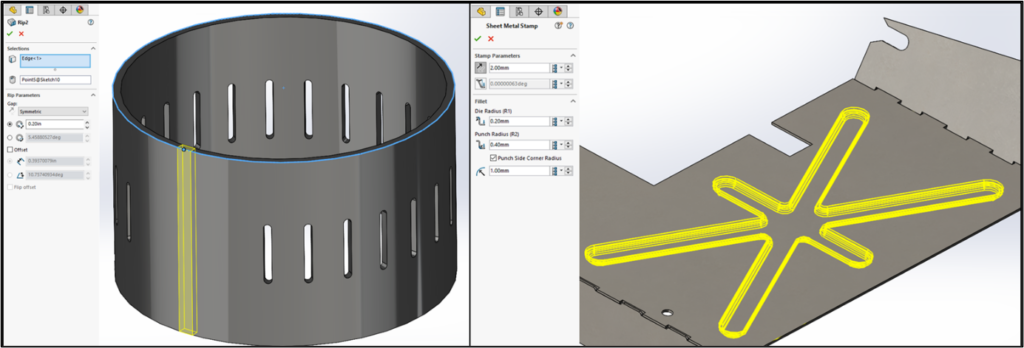

Stamping tool, propagate slots, and rip command for cylindrical/conical bodies are features that not only save time but also simplify the process of creating complex designs which are available in the latest release of SOLIDWORKS.

- SOLIDWORKS is highly adaptable and scalable, featuring an abundance of customized plug-ins, scripts, and macros. APIs also permit the integration of external applications for manufacturing and sales. Because of its comparatively simpler user interface, it requires less upkeep and training.

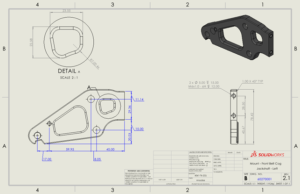

- Regarding the Drafting and Detailing activities, SOLIDWORKS provides the upper hand for the Design Engineer to create intuitive manufacturing data for the teams involved in the further process cycle to refer to & work seamlessly. It also overcomes the communication gap since it offers the relevant instructions (Bend Table, Punch Table & Hole Callout information) in the detailed drawing.

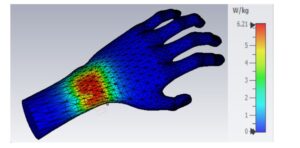

Now Design Your Sheet Metal Components on Browser with 3DSheet Metal Creator role on 3DEXPERIENCE Works Platform

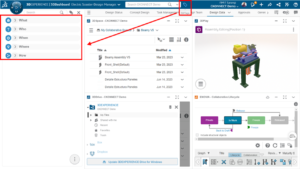

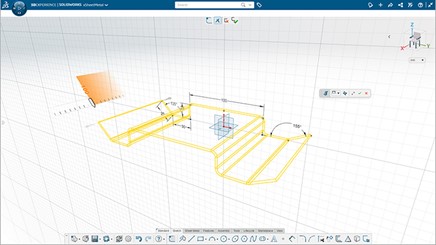

Currently, industries are moving towards Cloud Platform & want to design components on the move. 3DSheet Metal Creator role is the latest enhancement in 3DEXPERIENCE platform, which is an all-in-one 3D sheet metal design environment to create components with purpose-built, associative parametric sheet metal design tools. So, we can create design, fabricate & bring products faster to market with the power of 3DEXPERIENCE Works.

Get to know more about the 3DSheet Metal Creator role in detail through the first look video: xSheetMetal Creator – Drive Designs Faster With 3DEXPERIENCE xAPPS (youtube.com)

Remember that the little things count the most when it comes to success, and SOLIDWORKS can assist you in accurately and beautifully realizing your idea. Get in touch with Conceptia Konnect to learn more about how our state-of-the-art solutions can benefit your company.