Designers and manufacturers have increasingly turned towards plastic materials to develop new products because of less weight, less scrap, more affordable materials, and greater design flexibility. The major portion of these plastics are manufactured through the plastic injection molding process. Hence, the use of the injection molding manufacturing process is expanding every year.

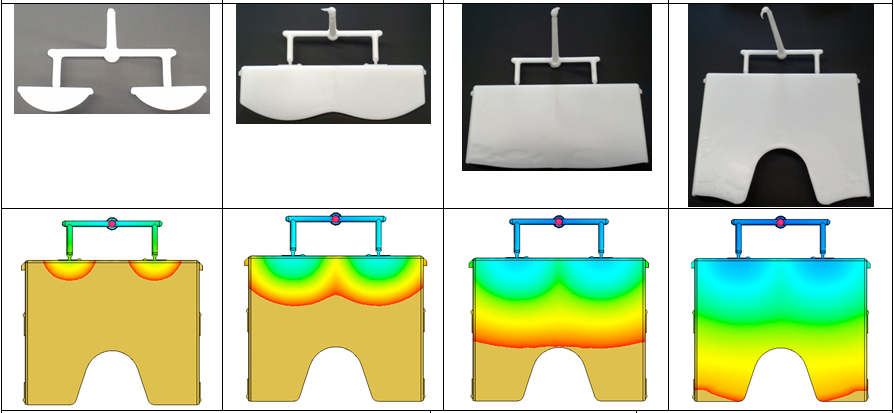

Designing and production of plastics part is a complex process. First, the part must be designed, next design the mold for that part and then send the mold design for manufacturing. When all of this is done, you can start producing plastic parts. However, still problems such as weld lines, air traps, sink marks short shots, voids shrinkage, warpage and deformation etc. are often found which will weaken the part and decrease the aesthetics of the part leading to loss in value of products produced

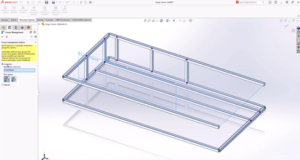

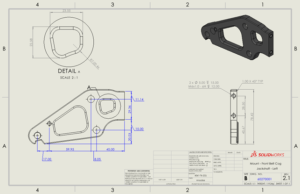

Prototyping plastic injection mold manufacturing is time-consuming and costly. Also, tooling iterations between plastic part designers and mold manufacturers is a lengthy process. To improve manufacturability and overcome these challenges of part manufacturing defects, injection-molding professionals can utilize SOLIDWORKS Plastics solution to cut time and cost from the process while simultaneously improving quality.

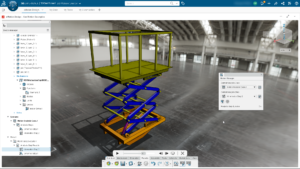

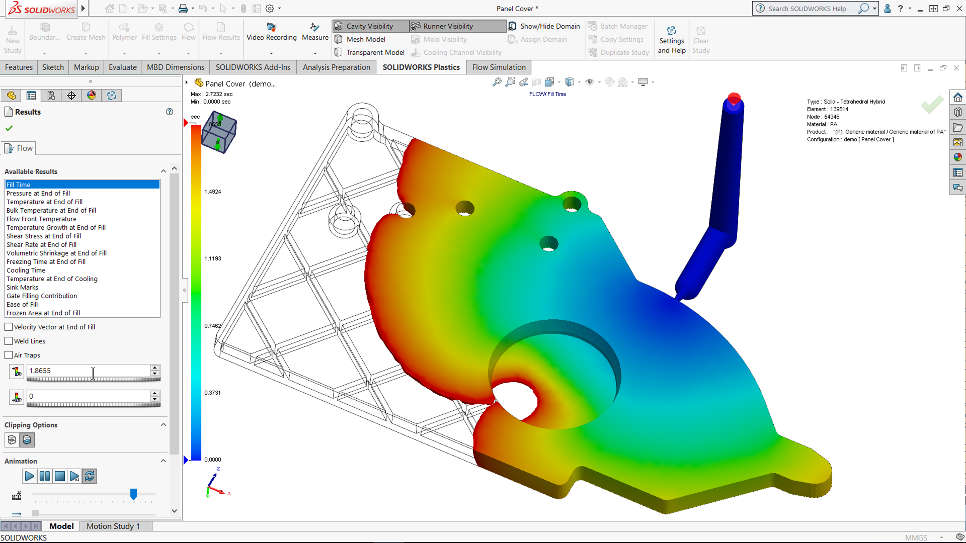

Plastic Injection Molding Simulation in SOLIDWORKS Plastics

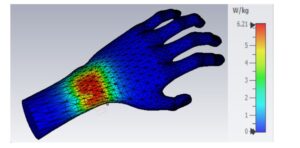

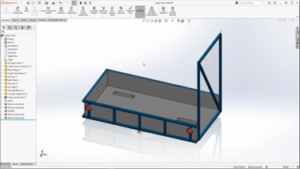

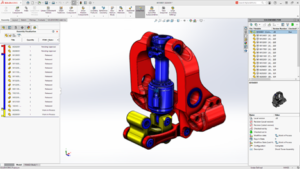

Perform Injection molding simulation with SOLIDWORKS Plastics directly on your 3D model along with SOLIDWORKS CAD interface, avoiding geometry translation and data loss issues. The impact of design changes carried in CAD environment can be witnessed right away in the simulation environment. The state-of-the-art, and powerful meshing technology covers geometries from thin-walled parts to solid parts. An intuitive interface with CAD like GUI leads you step by step to set up simulation study. The guided analysis, results advisor, and automated processes ensure correct setup followed even if you occasionally use simulation tools. The material database inside SOLIDWORKS Plastics contains thousands of commercial plastics and can be customizable as per your application. Thus, SOLIDWORKS Plastics makes it effortless for companies that create plastic parts or injection molds to predict and prevent manufacturing defects during the earliest stages of design

Benefits of SOLIDWORKS Plastics

- Easily Identify and rectify potential manufacturing errors during product design thus preventing manufacturing errors

- Decrease in cycle time of your product by reducing iterations between designers and mold makers

- SOLIDWORKS Plastics provides product designers, Moldmakers, and manufacturing professionals with the ability to simulate mold-filling operations accurately.

- This mold-filling simulation software provides quick and cost-effective insights needed to optimize designs and tooling.

- This solution can reduce mold prototyping requirements, especially when everyone associated with the development and production of injection-molded parts and tooling

- SOLIDWORKS Plastics helps to identify molding defects in the design stage and guides to rectify during design stage itself.

- SOLIDWORKS Plastics provides solutions for developing optimized balanced runner in family molds.

- The product designers are concerned about manufacturability of plastic parts, SOLIDWORKS Plastics has solutions that can assist to work smarter, faster, and better.

To Summarize, the increase in use of injection-molded plastic parts instead of conventionally machined metal parts brings many advantages for today’s product designers and manufacturers ranging from weight, scrap reduction and more importantly cost, to greater design flexibility through the production of more complex shapes and design geometries. However, for these benefits to grow to their greatest potential, boosting injection-molded design, tooling productivity, and achieving consistently high production quality has become critically important for success. Plastic part designers and manufacturers can increase the efficiency and performance of their injection molding process by supporting traditional, trial-and-error prototype mold iterations with the SOLIDWORKS Plastics mold-filling simulation solution.