In the existing scenario of rapid growth of industrial development, to retain their existing customers and to attract the new visitors industries want to deliver only their best products in a very shorter lead time. Due to this, the product designers are enforced to make the design and release the drawings in a less span time. Moreover for the working on RFQ’s they need to represent the exact BOM data along with the pricing, which basically based on their design variations.

Due to this issue, the design automation scenario comes in to the picture of design development department. To implement the design automation, apart from their regular design activities, engineers are forced to learn the programming languages and define the design codes in to the existing software to enhance it.

This makes the design engineers to feel that they are under the tremendous pressure of handling multi-phase works. This impacts in their regular design works and it leads to the loss of design productivity, brunch of bugs in their design programming codes, etc.

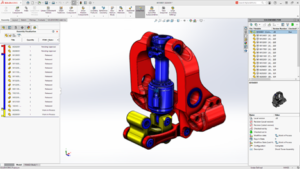

SOLIDWORKS Design and Drawing Automation

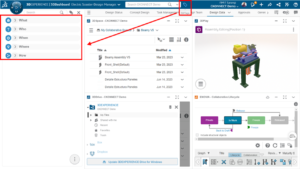

Effectively to answer for these issues, SolidWorks comes with a solution for design automation which never expects the expertise of the design engineers in the area of programming languages of the software. Added to its immense capability SolidWorks comes with a tool named as, “DriveWorks” which works especially for the design automation and the tool is defined by the Rules driven one and not by the programming languages.

Benefit of rules driven design automation in SolidWorks.

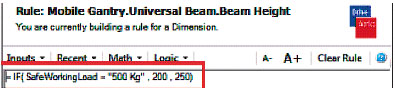

- The design automation process can be defined by the design engineers by assigning the rules using mathematical and logical operators.

- It can be understood by anyone in the design process and easily re-editable.

- Product range limitations can be known and controlled easily.

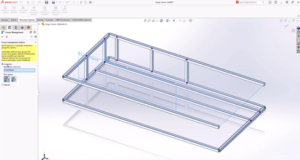

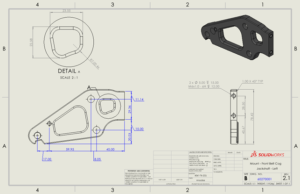

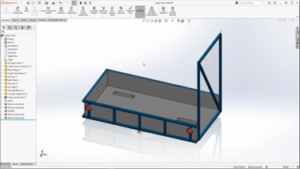

The dimensions of the features will be captured in the screen for the modification based on the defined rules in the rules sheet. When the design change request is initiated the rules will be applied for the modification and the drawings are generated automatically along with the BOM and costing for the same by the software for the new design which was requested.

Conclusion

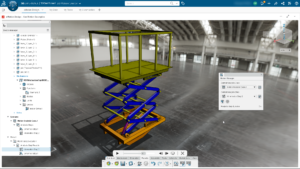

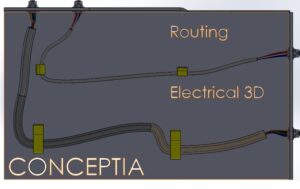

SolidWorks design automation tool usage is not limited to a particular industrial application and it serves for the different verticals like, machine design, plant design, precision equipment, medical appliances, power plant designs, cranes & elevator designs and so on.

Based on the customer requirement the design modification request is required as an input to the software and based on the input it will solve the designs automatically referring to the defined rules. As an output, the SolidWorks will deliver the detailed design and manufacturing drawings of the requested design along with the updated BOM. This will be generated during the RFQ stage and once the order is confirmed the entire set of drawings can be released for the manufacturing at no matter of time. This will reduce the huge time invested in the design process which “saves money”.

SolidWorks was developed with high levels of technology adaptions, which enables the design department to work in a risk free approach to do the product development in the fastest manner possible. SolidWorks design automation tool provides the facility for the manufacturers with an adoption to higher productivity at lesser time integration.

S VinothKumar

Sr. Application Engineer