Easily and Accurately Optimize Your Plastics Part Design and Manufacturability with SOLIDWORKS Plastics

Designers and manufacturers have increasingly turned towards plastic materials to

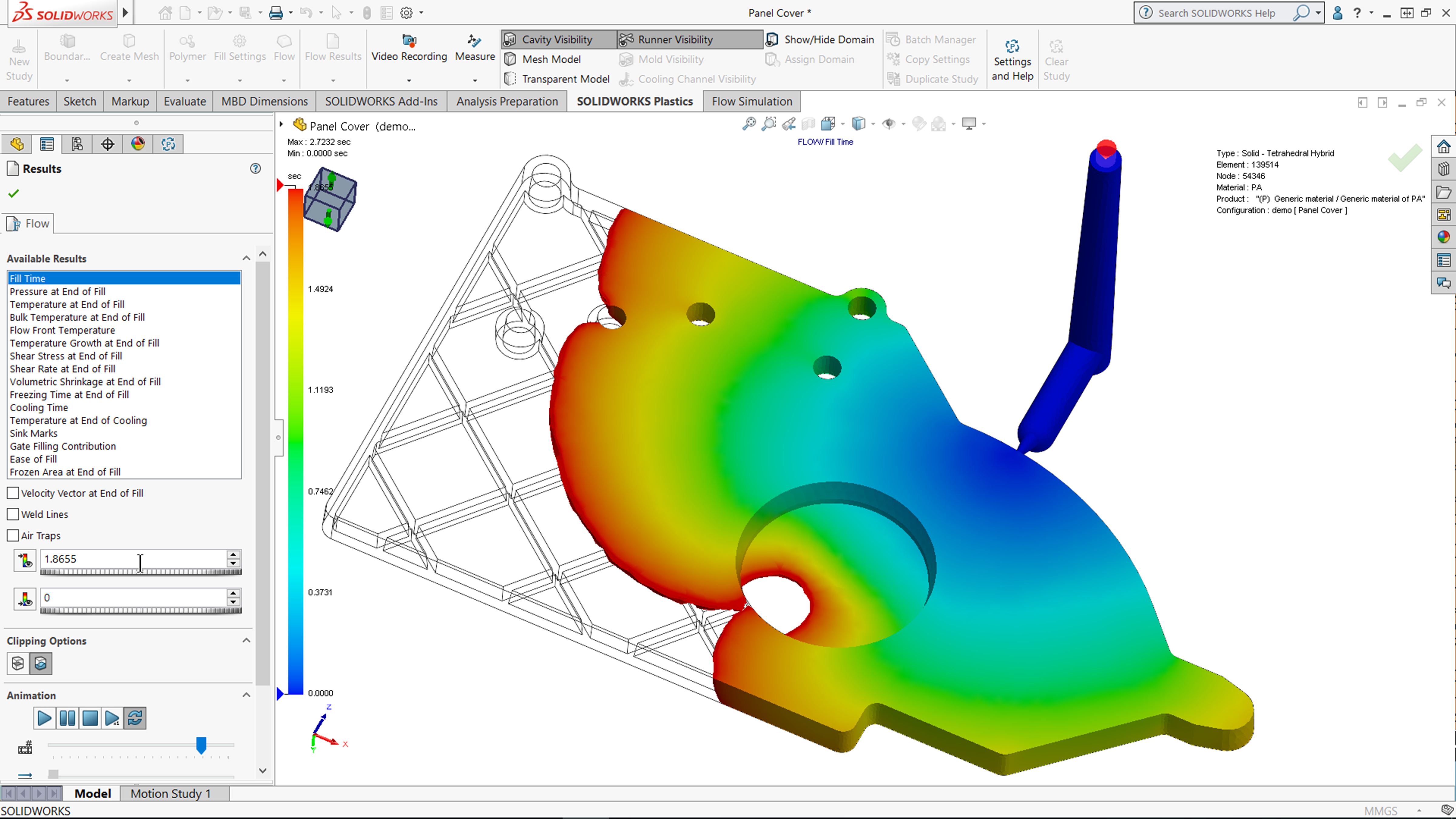

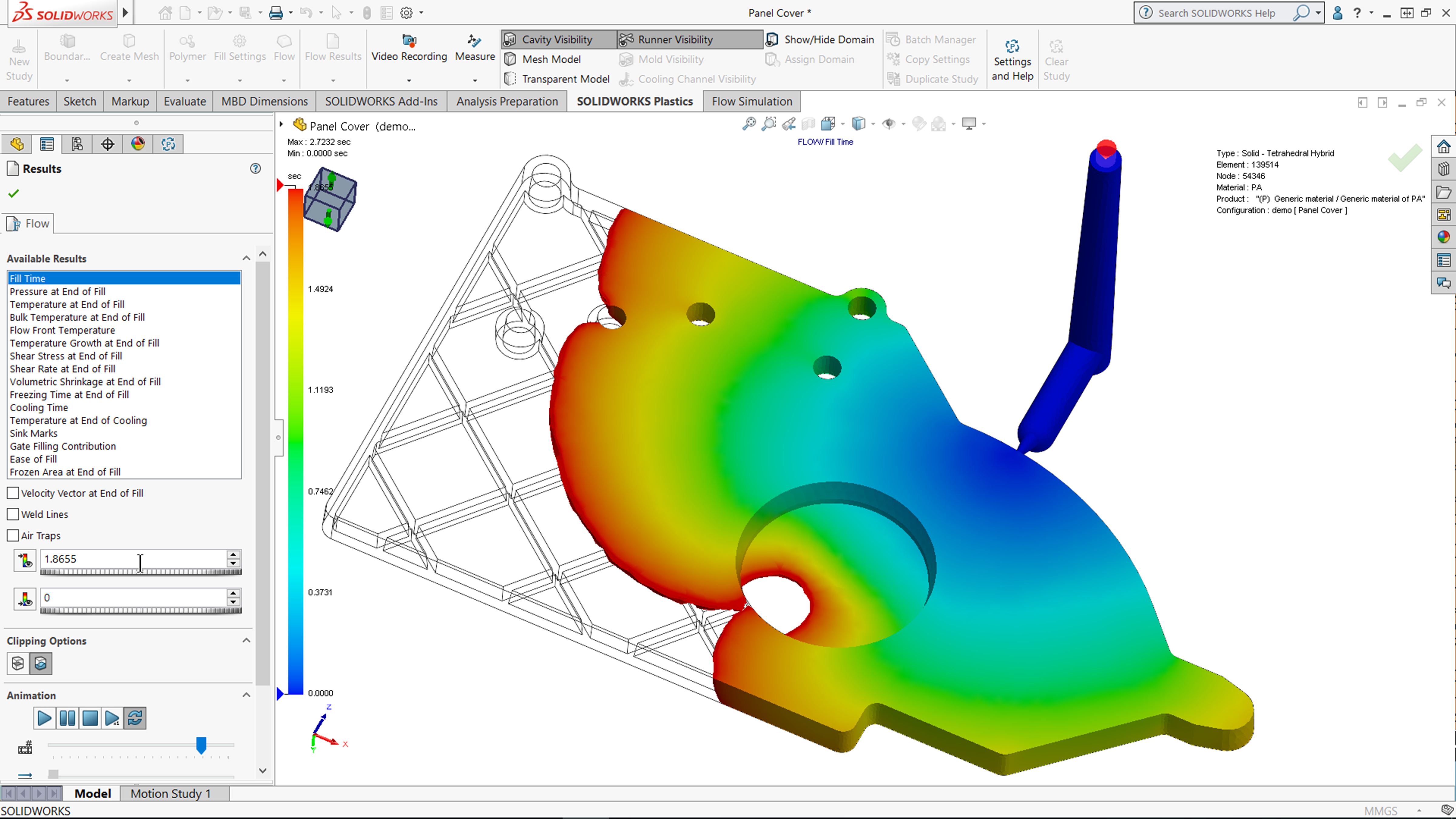

SOLIDWORKS Plastics Solutions Enable to Predict Defects and Avoid Costly Mold Rework

SOLIDWORKS Plastics is simple and easy to use and learn which helps to optimize plastic parts and injection mold designs.

SOLIDWORKS Plastics material database contains thousands of commercial plastics that are customizable and help in material selection in the design process.

A flawless mold will work effectively without any rework by detecting the manufacture defects while designing itself.

Through analyzing the mold system with SOLIDWORKS Plastics you will optimize the size of the injection molding machine, reduce a scrap of plastic material to estimate cycle time.

It will function in a fully embedded SOLIDWORKS 3D CAD environment to optimize product designs and improve manufacturability.

Web-based HTML reports make it easy to communicate simulation insights and design recommendations to all the members in the design team to manufacture teams.

Use SOLIDWORKS Plastics Solutions to optimize sprues, runners, and gate systems to determine the best mold layout.

Mold tool engineers can analyze all the cooling lines in the mold layout to reduce cycle time.

SOLIDWORKS Plastic Products as an integrated solution will help all sizes of companies to innovate and grow their business. You can contact at 9590506408 for best price details, offers, and best quote. You can request for Quote directly here https://ckonnect.in/solidworks/get-a-quote/

Designers and manufacturers have increasingly turned towards plastic materials to

Topology optimization is the most common type of structural optimization.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

+91 9590506408