fe-safe

Durability Analysis Software for Finite Element Models

fe-safe

Industry is putting increasing pressure on manufacturers to use less material to deliver lightweight but stronger components, lower warranty and recall costs and all in less time.

Many companies use advanced Finite Element Analysis to calculate design stresses, but the fatigue analysis is often still done by manually picking stress points for spreadsheet analysis. This is time-consuming and unreliable because it is easy to miss failure locations.

Many companies use advanced Finite Element Analysis to calculate design stresses, but the fatigue analysis is often still done by manually picking stress points for spreadsheet analysis. This is time-consuming and unreliable because it is easy to miss failure locations.

Component validation by fatigue testing a prototype design in the test lab is time-consuming. If the prototype fails prematurely, a costly, open-ended cycle of design-test-redesign may be required. Project time-scales slip and delivery is late.

fe-safe, from the SIMULIA brand of Dassault Systèmes, is the world’s leading technology for durability analysis. Its capabilities have been developed to meet the most demanding industry applications. fe-safe is used by leading companies in the automotive, truck, off-highway, marine, military, off-shore, power generation, wind energy, medical engineering and many other industries.

fe-safe has been developed continuously since the early 1990s in collaboration with industry to ensure that it continues to set the benchmark for fatigue analysis software. fe-safe was the first commercially available fatigue analysis software to focus on modern multiaxial strain based fatigue methods.

fe-safe, from the SIMULIA brand of Dassault Systèmes, is the world’s leading technology for durability analysis. Its capabilities have been developed to meet the most demanding industry applications. fe-safe is used by leading companies in the automotive, truck, off-highway, marine, military, off-shore, power generation, wind energy, medical engineering and many other industries.

fe-safe has been developed continuously since the early 1990s in collaboration with industry to ensure that it continues to set the benchmark for fatigue analysis software. fe-safe was the first commercially available fatigue analysis software to focus on modern multiaxial strain based fatigue methods.

WORKFLOW

LOADINGS

fe-safe can predict fatigue lives from a range of loading types:

- Single load time history applied to a linear elastic Finite Element model

- Multiple time histories of loading superimposed in fe-safe (more than 4000 load histories can be applied)

- Sequence of FEA stresses (elastic or elastic-plastic, linear or non-linear)

- Superimposition of steady state modal solutions

- Superimposition of transient dynamic modal solutions

- PSD loading, block loading test programs, rainflow cycle matrices

- Effects of forming or assembly stresses can be included

fe-safe includes a powerful, simple-to-use batch command system, with on-line parametric variation for ‘sensitivity’ studies.

ANALYSIS METHODS

fe-safe includes a powerful, simple-to-use batch command system, with on-line parametric variation for ‘sensitivity’ studies.

- fe-safe includes a wide range of analysis methods, all of which are included in the standard package: Strain-based multiaxial fatigue algorithms—axial strain, shear strain, Brown-Miller with a multiaxial Neuber’s rule and cyclic plasticity model

- Dang Van multiaxial fatigue for high cycle design

- Advanced analysis methods for fatigue of cast irons

- High temperature fatigue

- Automatic detection of surfaces

- Comprehensive element/node group management

- Critical distance algorithms

- New method for fatigue analysis from PSDs of loads. Combines a unique method of superimposing multiaxial PSDs with critical plane analysis

- S-N curve analysis including multiaxial fatigue using axial stress or a new Brown-Miller analysis formulated for use with S-N curves

- Plots of material data including the effect of temperature, strain rate etc.

- Analysis of welded joints

- Analysis from elastic and elastic-plastic FEA stresses, linear and non-linear analysis

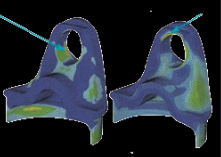

- Automatic detection of fatigue hot-spots

- Stress gradient corrections

- Critical plane methods for random vibration fatigue

- Analysis of rotating parts

fe-Safe Key Benefits

With fe-safe as an integrated part of your design process, you have the ability to:

- Optimize designs to use less material

- Optimize and validate design and test programs

- Reduce prototype test times

- Increase confidence that your product designs pass their test schedules as “right first time”

- Reduce product recalls and warranty costs

- Improve correlation between test and analysis within a single user interface

- Speed up analysis times, thereby reducing man-time hours

fe-safe includes direct interfaces to leading FEA suites. Interfaces are driven from an intuitive, single

screen, Windows-based GUI.