Product Data Management (PDM) is a systematized approach used by businesses to efficiently organize, control, and manage product-related data throughout its lifecycle. It encompasses various digital assets such as design files, technical documentation, specifications, and related information crucial for product development and manufacturing processes.

What is PDM (Product Data Management)?

Product Data Management (PDM) is a comprehensive system or set of processes used to manage and control all aspects of product-related data throughout its lifecycle within an organization. It focuses on organizing, securing, and maintaining digital information associated with a product from its inception through design, manufacturing, distribution, and beyond.

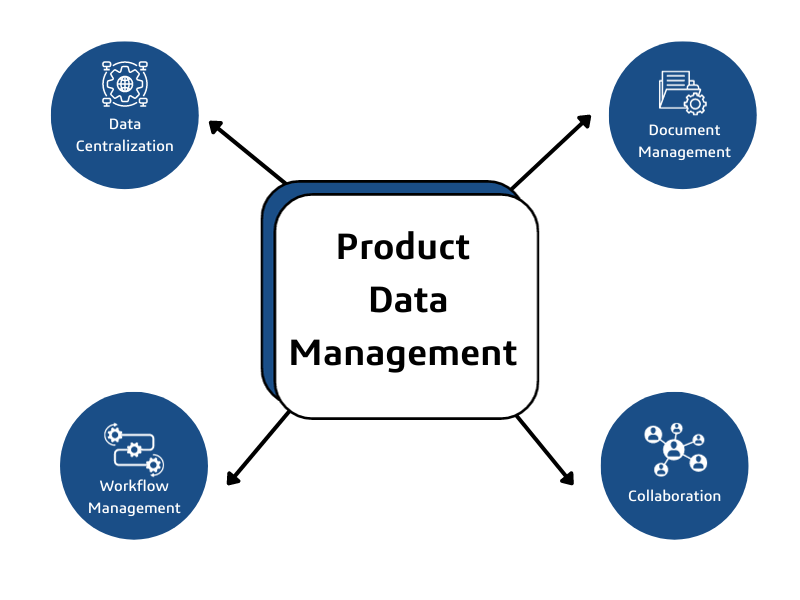

Core elements of PDM:

- Data Centralization: PDM centralizes all product-related data into a single repository, making it easily accessible and manageable by authorized users.

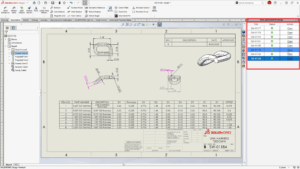

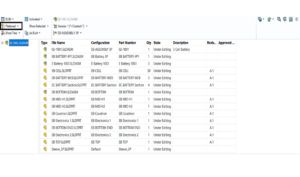

- Document Management: PDM involves managing various types of documents, including CAD models, drawings, specifications, bills of materials (BOMs), and related technical documentation.

- Workflow Management: It streamlines processes by defining and automating workflows, ensuring that tasks move efficiently through various stages of product development.

- Collaboration: PDM allows for seamless collaboration among team members, departments, and even across geographical locations. It ensures everyone is working with the most up-to-date information.

Why PDM?

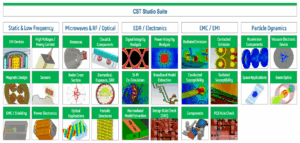

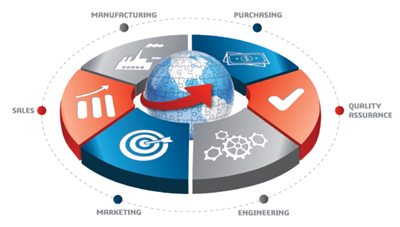

Product Data Management (PDM) is a comprehensive system used to manage and control all aspects of a product’s data throughout its lifecycle. It’s particularly crucial in industries like manufacturing, engineering, and design, where managing vast amounts of data related to products is essential.

Key Components of PDM:

- Efficiency: PDM systems streamline workflows, making it easier to manage and access critical product data. This efficiency leads to time savings and reduced errors in product development.

- Version Control: It helps maintain proper versioning of designs and documents, preventing confusion or errors caused by outdated or conflicting versions.

- Compliance and Security: PDM systems often include robust security measures to protect sensitive data. They also help ensure compliance with industry standards and regulations.

- Cost Savings: By optimizing workflows and reducing errors, PDM systems contribute to cost savings in product development and manufacturing processes.

- Innovation and Time to Market: By streamlining processes, PDM can accelerate innovation cycles and help bring products to market faster, giving companies a competitive edge.

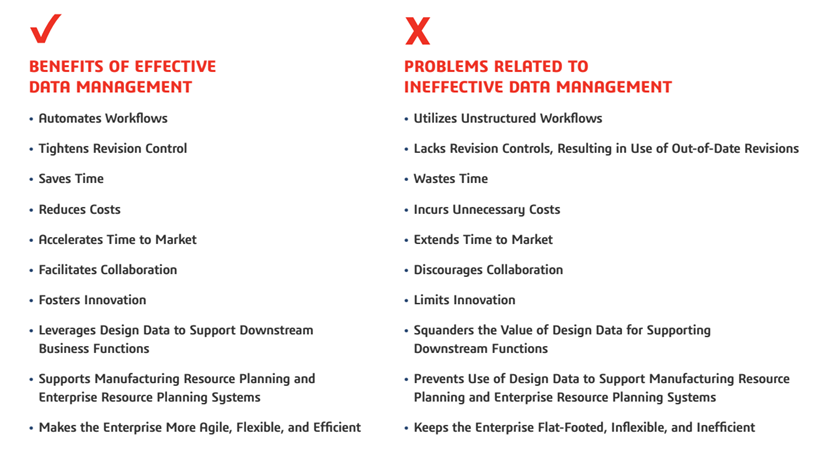

Advantages of Effective Data Management when compared to ineffective Data Management

SOLIDWORKS PDM:

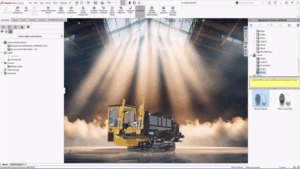

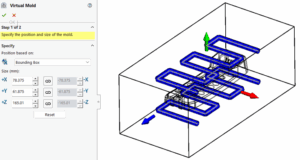

SOLIDWORKS PDM (Product Data Management) is a software solution designed by Dassault Systèmes SOLIDWORKS Corp. It’s a powerful tool for managing and controlling design data, documents, and processes within the realm of engineering and product development. PDM systems like SolidWorks PDM offer various features:

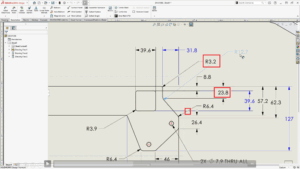

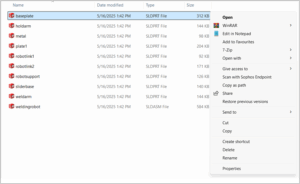

- File Management: Centralized storage for CAD files, documents, and other related files, ensuring version control and preventing data loss or accidental overwrites.

- Revision Control: Tracks changes made to files, maintains a history of revisions, and allows for easy retrieval of previous versions.

- Integration with CAD software: Seamless integration with SOLIDWORKS and other CAD software, allowing for efficient file handling and design collaboration.

Data Searching and Retrieval: Offers robust search capabilities to quickly find and retrieve files based on metadata, keywords, or other specified criteria

SOLIDWORKS PDM aims to stabilize the design and development process, enhance collaboration among team members, and ensure data integrity and security. It’s precious for larger teams or organizations working on complex engineering projects where managing design data and version control are crucial.

SOLIDWORKS PDM is a robust and essential tool for businesses and teams engaged in engineering, design, and product development. Its core capabilities address critical needs in managing design data, streamlining collaboration, and ensuring version control and data integrity. Overall, SOLIDWORKS PDM streamlines design processes, enhances productivity, and mitigates risks associated with data management and collaboration. It’s an invaluable tool for organizations striving to maintain efficiency, accuracy, and data integrity throughout the product development lifecycle.