Plastics have become an integral part of our day-to-day life due to their distinguished properties in comparison to other materials. Under the current market scenario, companies under the industry verticals such as Consumer Products, Transportation & Mobility, Life Science, & High Tech are heavily dependent on plastics. Currently, 80% of plastic components in the market are produced using the Injection Molding technique. It is commonly used in the mass production of identical components with strict tolerance.

Below are the major challenges faced by traditional injection molding companies. They initially design the mold, prototype, check for defects & then make changes in molds and process continues untill the first molded part is obtained as per their requirement.

- Manufacturability of design

- More rounds of mold prototyping accompanied by design changes

- Increased design development cycle time

- Unable to predict the mold defects & further requires mold redesign

- Material Selection

- Cost & Time constraints

In this blog, we will discover the various capabilities of SOLIDWORKS Plastics solutions for industries in the Design-to-Manufacture cycle.

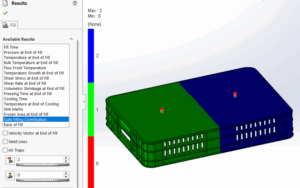

SOLIDWORKS Plastics is an Injection Molding process simulation solution that can work as an add-in in the SOLIDWORKS Desktop or SOLIDWORKS Connected application that predicts the flow of melted plastic material flows inside the mold cavity. The four analyses, which can be performed in SOLIDWORKS Plastics, are based on the production steps.

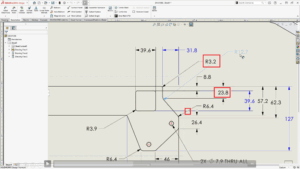

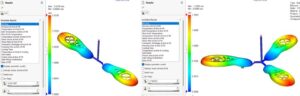

- Filling – Predicts the filling of molten plastic inside the material and helps us identify defects such as short shots, air traps, sink marks and weld lines.

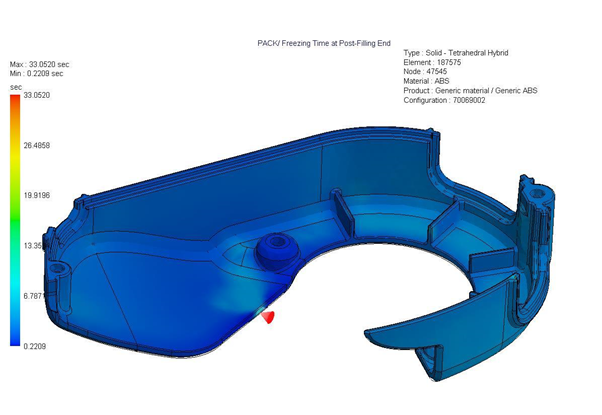

- Packing – Holds the mold filling pressure to ensure mold is completely filled and we check the gate freezing and holding tonnage for mold (if any).

- Cooling – Optimization of cooling system and solidification of part can be analysed. Overall cycle time of Injection Molding is also calculated.

- Warp – Focused on identifying the distortion/deformation of ejected part due to various stresses involved in the process.

Capabilities of SOLIDWORKS Plastics:

While adopting SOLIDWORKS Plastics in your product development cycle, customers will be benefitted through its distinguished capabilities as follows;

- Expanded Plastics Materials Database comprising around 4,200 materials and option to customize material

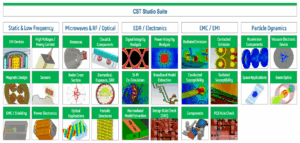

- Advanced Injection Molding analysis – insert overmolding, multi shot overmolding, gas or water-assisted injection, co-injection and more.

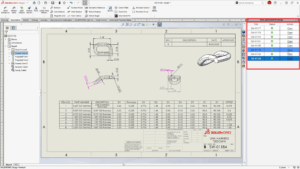

- Simply export the results as detailed iteration study with images/videos in word, powerpoint or html file format under report generation option.

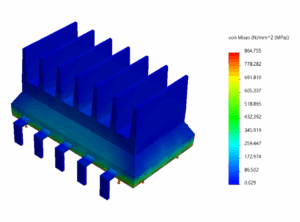

- Export results (in-molding & de-molding residual stress) from Plastics to other structural analysis studies in applications such as ABAQUS, ANSYS, Digimat & SOLIDWORKS

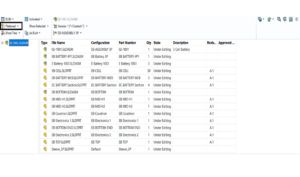

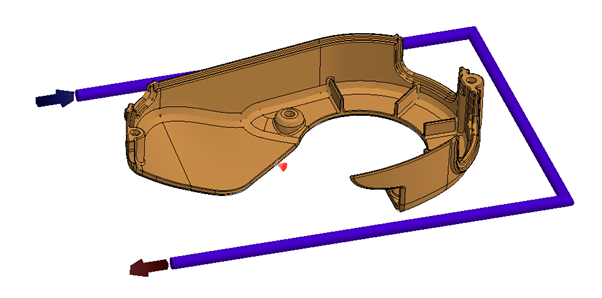

- Evaluate Mold Geometry with respect to runner balancing and multi-cavity filling

- Automate the simulation study by creating duplication of existing study (with/without results) and run simultaneous studies using Batch Manager.

Benefits of SOLIDWORKS Plastics over Traditional approach:

SOLIDWORKS Plastics provides the leverage of customers to overcome the difficulties faced by them during the Injection Molding process through the following advantages;

- Easily compare the flow of molten plastic for different material using duplicate study option, which results in faster time-to-market of product.

- Automated & Guided mesh (Solid/Shell) generation with more control over refinement (Global/Local) allowing you to get the results more precise and faster.

- Predict the manufacturing related defects and mitigate them at the early stage of product development thereby reducing the cost & time involved in prototyping.

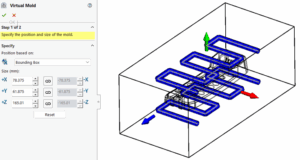

- Ensure the component is manufacturable or not using the thickness/geometry evaluation option.

- Avoid mold expensive rework by optimizing the design of gate positions, cooling system and runner system through analysis & advisors.

SOLIDWORKS plastics offers a whole lot of tools/features that enhance the new product development process for organizations, that rely heavily on plastic components. The software provides various capabilities that can be instrumental in current competitive market starting from design optimization, cost reduction, improving quality of finished part and speeding up the time-to-market. By integrating SOLIDWORKS Plastics in their workflow, industries can exceed their customer expectations thereby delivering high-quality products efficiently.

If you are looking to enhance the product development process in your organization and want to stay ahead of your competition, kindly go through the SOLIDWORKS Plastic Portfolio. If you are from an industrial vertical that utilizes plastic components majorly, SOLIDWORKS Plastics is one which you can help you achieve the design and manufacturing goals. Contact us today for a demo or consultation and see how our solution can revolutionize your product development experience.