SOLIDWORKS CAM

Integrated Design and Manufacturing processes under one system to evaluate designs

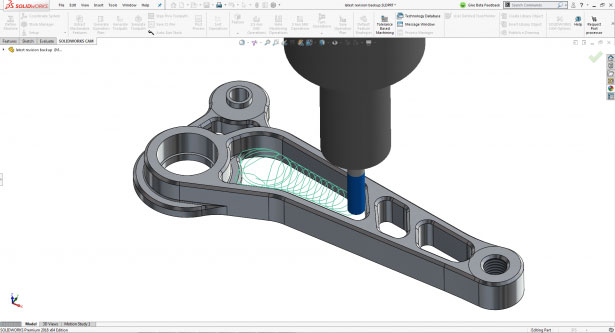

SOLIDWORKS CAM – Integrated, Knowledge Based Machining Technology

SOLIDWORKS CAM Powered by CAMWorks is an integrated 2.5-axis milling and 2-axis lathe programming solution by SOLIDWORKS. By utilizing the emerging technologies of Model Based Definition and Knowledge Based Machining, This can rapidly transform your Design to Manufacturing process by improving communication, reducing errors, reducing cycle times, and increasing your product quality.

It leverages the rich content in the 3D CAD model to speed up product development and reduce error prone, time-consuming, repetitive manual steps in the current development process, like programming CNC machines. Knowledge Based Machining (KBM) is the foundation for streamlining the programming process, learning as you program which frees up your time to focus on the critical areas of the components.

SOLIDWORKS CAM is 2.5 axis milling and turning. 2.5 axis will also cover Laser, Waterjet and Plasma cutting

Key Features of SOLIDWORKS CAM

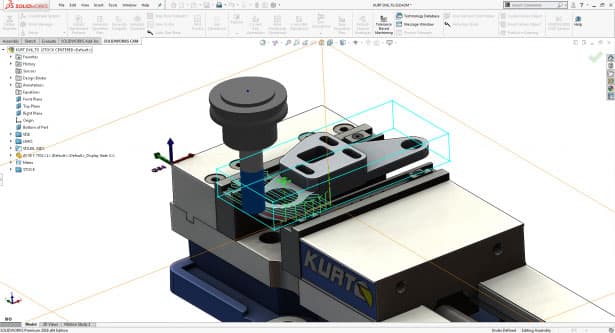

Automatic Feature Recognition

- SOLIDWORKS CAM is a feature-based CAM system; that means we define features from the solid model to machine.

- These features can be created on native SOLIDWORKS parts or imported components using 3D Interconnect.

- There are two ways to create features within SOLIDWORKS CAM: Automatic and Interactive.

Rules-Based Machining

- SOLIDWORKS CAM is built on rules just like our designers leverage today. With features defined in it, we can automatically create strategies, select tools, set feeds/speeds, patterns, depth of cut and all the options required to machine that feature.

- The rules are stored in SQLite through an easy-to-use interface that allows you to share this knowledge with everyone throughout your organization. This allows the designers and estimators to leverage the rules and standard practices used in the manufacturing process.

Tolerance-Based Machining

- The biggest advantage of Rules-Based Machining for designers and programmers is the ability to read MBD data within the SOLIDWORKS part file.

- This will understand the tolerances within a given part file and change machining strategies accordingly.

High-Speed Machining

- SOLIDWORKS CAM utilizes VoluMill technology provided by CAMWorks. This science-based toolpath allows users to increase output while extending tool life and reducing machine wear.

- VoluMill maintains constant tool pressure through the cut. This is accomplished by understanding the tool path, cutter, and the feed and speed work together.

- Traditional high-speed machining tool paths are just one constant feed rate through the cut. This creates a shock load on the tool, part, and machine. By varying the toolpath through the cut, the shock load is reduced, which leads to shorter production times at a lower cost.

- It allows you to streamline the manufacturing process by capturing standard workflows, reading MBD tolerances, and extending the life of tooling and equipment.

Download SOLIDWORKS CAM Product Matrix

Our Customer Testimonial

“SOLIDWORKS is the best user-friendly platform, which helps formulate simple to complex designs. SOLIDWORKS is an interactive learning environment that supports technological advancements in today’s world.”

Clanston Viegas – Lead Design Engineer