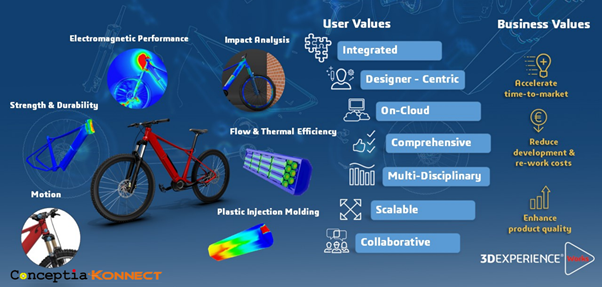

The Electric Vehicle (EV) Industry is growing tremendously right now, leading to the advancement in the field of automotive design & manufacturing. As the demand for EVs in the market has been increasing, safety & compliance requirements arose, leading to numerous challenges for technologists to improve in terms of efficiency, range, sustainability, and so on. To meet the growing demand & minimize the time constraints in the design to manufacturing cycle, SOLIDWORKS 3D CAD & its portfolio of solutions revolutionizes the approach of engineers in EV Design, enabling them to tackle the challenges put forth against them with precision and efficiency. The MOD-SIM (Modelling & Simulation) approach available in 3DEXPERIENCE Works streamlines the workflows by enhancing collaboration & bringing ground breaking EV concepts to life faster than ever before.

So, in this blog, we will explore how these solutions address the unique challenges in Electric Vehicle Design Development and how they empower engineers to achieve beyond the boundaries of innovation and contribute to a more sustainable future.

Challenges faced by EV Manufacturers with respect to Design & Validation Stage:

EV manufacturers encounter the following difficulties during the design and validation stages. We have outlined some specific difficulties faced, mostly by different EV Industries, during these stages.

- Structural Integrity

- Regulatory compliance

- Materials selection

- Cost and time constraints

- Battery integration and optimization

- Range and efficiency

- Management of Electrical and Thermal systems

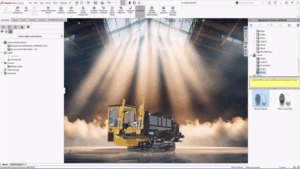

Transform EV Design with SOLIDWORKS and 3DEXPERIENCE Works

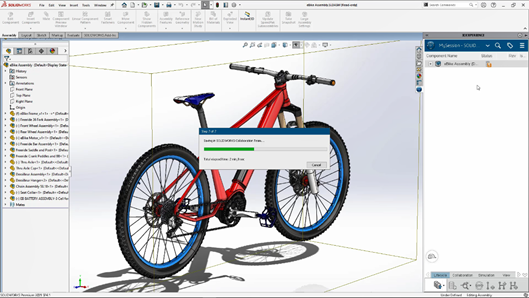

With respect to 3D design and conceptualization in the design development stages, SOLIDWORKS 3D CAD and browser-based tools (3DCreator and 3DSculptor roles) can be instrumental. These tools help you develop designs on the go and use them in your detailed design through SOLIDWORKS 3D CAD. 3DEXPERIENCE Works enhances the capabilities of cloud-based user experience for collaboration, data management, and lifecycle management.

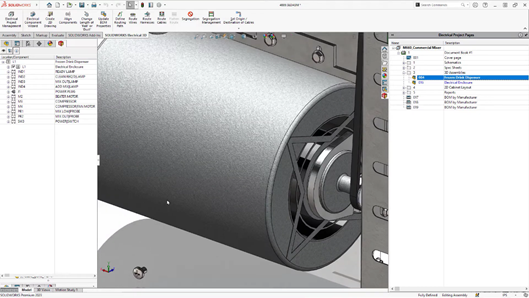

Streamlining EV Electrical Systems with SOLIDWORKS Electrical:

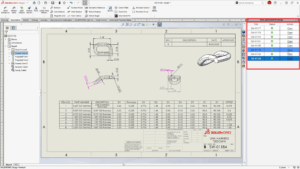

SOLIDWORKS Electrical Solutions offers a comprehensive suite of tools that streamline the creation and integration of electrical systems within Electric vehicles (EVs). This enables electrical engineers to combine schematic design capabilities with mechanical 3D CAD modelling. Significant features include single-line and multi-line schematics, cabinet creation, and advanced report generation, which facilitate a more efficient design process and reduce the time spent on design.

Enhancing EV Validation with SOLIDWORKS Desktop Simulation & 3DEXPERIENCE Simulation:

An essential part of the development process for electric vehicle (EV) manufacturers is now the validation of EVs. Robust simulation tools that can forecast real-world behaviour are increasingly needed to ensure that every component satisfies strict standards. SOLIDWORKS Desktop Simulation & 3DEXPERIENCE Simulation offer robust solutions to enhance EV validation, providing engineers with the necessary insights to optimize designs and ensure reliability.

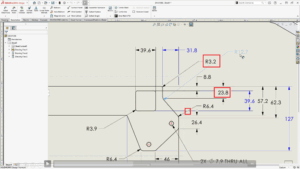

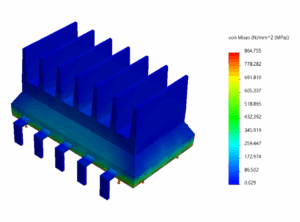

Comprehensive Structural Analysis:

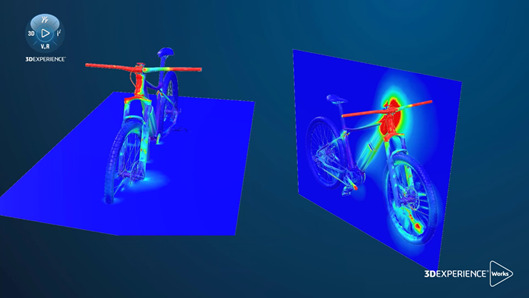

One of the primary concerns in the EV design development process is the structural integrity, especially given the added weight & unique placement of batteries. SOLIDWORKS Structural Simulation caters to the need of FEA analysts with respect to detailed structural analysis. This solution enables the simulation of various load conditions, including impacts & vibrations, to ensure the vehicle frame & components can withstand real-world stresses. This is very crucial in analysing whether the structure is crashworthy and ensures passenger safety. If not, we can make desirable changes even before the prototyping stages.

Thermal Management Optimization:

It is essential to maintain heat generated in electric vehicles for the performance & longevity of the battery. The advanced thermal analysis capabilities are offered in both SOLIDWORKS Desktop Simulation and 3DEXPERIENCE Works, allowing the validation team to simulate the heat distribution & dissipation in EV, ensuring that all components are operating efficiently within the optimal temperature ranges.

Aerodynamics:

With the flow analysis simulation capabilities in SOLIDWORKS Desktop Simulation and 3DEXPERIENCE Works, engineers can perform detailed fluid dynamics analysis to study the flow of air around their electric vehicle design. This helps identify areas of drag, with which we can improve our design to reduce resistance, thereby improving efficiency.

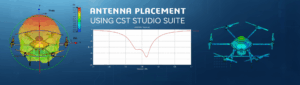

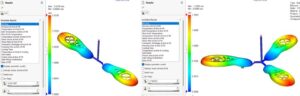

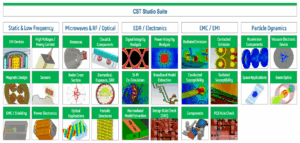

Ensuring Electromagnetic Compatibility (EMC) in EVs with CST Suite:

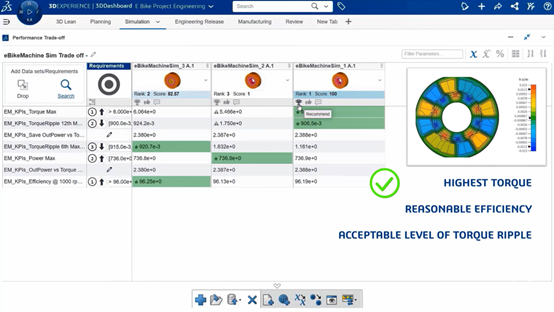

Designing electric vehicles that meet compliance standards and rating validations requires careful consideration of the assessment of electromagnetic analysis. High-performance 3D electromagnetic analysis software, CST Studio Suite, is essential for designing, analysing, and optimizing electromagnetic systems and components within a single interface. Low-frequency electromagnetic simulation, which covers statics to high-frequency applications, can improve designs and anticipate possible problems specifically for electric vehicles.

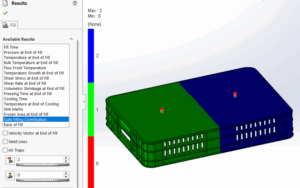

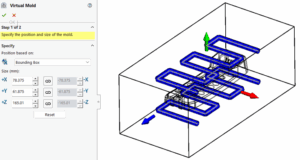

Simulating Injection Molding of Plastic parts:

SOLIDWORKS Plastics & Plastics Injection Engineer role in 3DEXPERIENCE Works: We have the capability of simulating injection molding for plastic parts used in EVs. We can predict defects very early and make improvements in design, thereby reducing the prototyping cost and time involved.

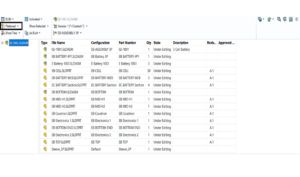

Cloud-Based Collaboration and Scalability:

One of the standout features of 3DEXPERIENCE Simulation is its cloud-based platform, which facilitates collaboration and scalability. Engineers can access simulation tools from anywhere, collaborate in real time, and share data seamlessly across teams. This flexibility accelerates the validation process, reduces development cycles, and allows for the scalability needed to handle complex simulations efficiently.

In summary, a major advancement in the design of electric vehicles (EVs) has been made with the integration of a modeling and simulation-based approach using SOLIDWORKS 3D CAD and validation solutions. Performance, safety, and efficiency are maximized from the start thanks to this synergy that enables engineers to produce more precise and dependable electric vehicle (EV) models. To predict performance metrics like range, power consumption, and thermal management requirements, it is easier to gain a thorough understanding of the vehicle’s operational characteristics when MOD-SIM is used.

Meanwhile, SOLIDWORKS 3D CAD provides a robust platform for detailed design work, enabling the creation of precise components and systems that are essential for the next generation of EVs. Validation tools further enhance this process by allowing for virtual testing and refinement of designs, reducing the need for costly physical prototypes. As the EV market continues to expand, the combination of SOLIDWORKS 3D CAD and validation solutions will be indispensable for designers looking to innovate and lead in this dynamic field. This approach not only streamlines the design process but also accelerates the development cycle, ensuring that new EV models can meet the rapidly evolving demands of consumers and regulatory bodies alike.

I hope you understood the detailed insight on how EV manufacturers can use our Product development solutions for the Electric Vehicle (EV) design development process. You can reach out to us to have a technical discussion on how we can provide the perfect solution in the design-to-manufacture cycle of your existing process.