What is MODSIM (MODelling and SIMulation)?

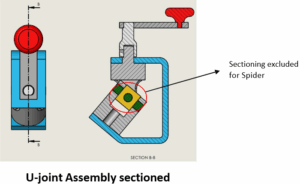

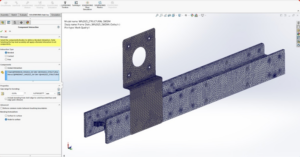

Traditionally, product development in an organization follows series of process where, a design engineer designs a product that meets its intended design intent and criteria. Then the design is shared with simulation team for testing the product virtually for multiple loading scenarios and conditions. If simulation team suggests changes due to product failure when it is tested virtually for real world scenarios, then it goes back to design team and this cycle repeats till the product suffices both design intent and functionality. This process take longer time to get the product faster to the market. Imagine evaluating multiple design alternatives for innovative and efficient product with this approach.

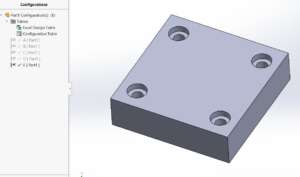

MODSIM – MODelling and SIMulation, is a lean approach to engineering that can revolutionize the productivity of engineers and product teams. It is a technology where the product development process is data-driven, collaborative, and concurrent approach that will help in creating the better products faster.

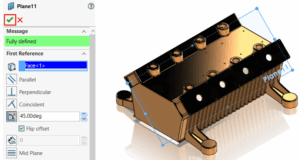

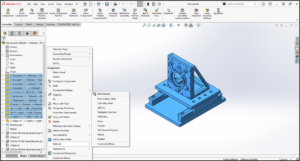

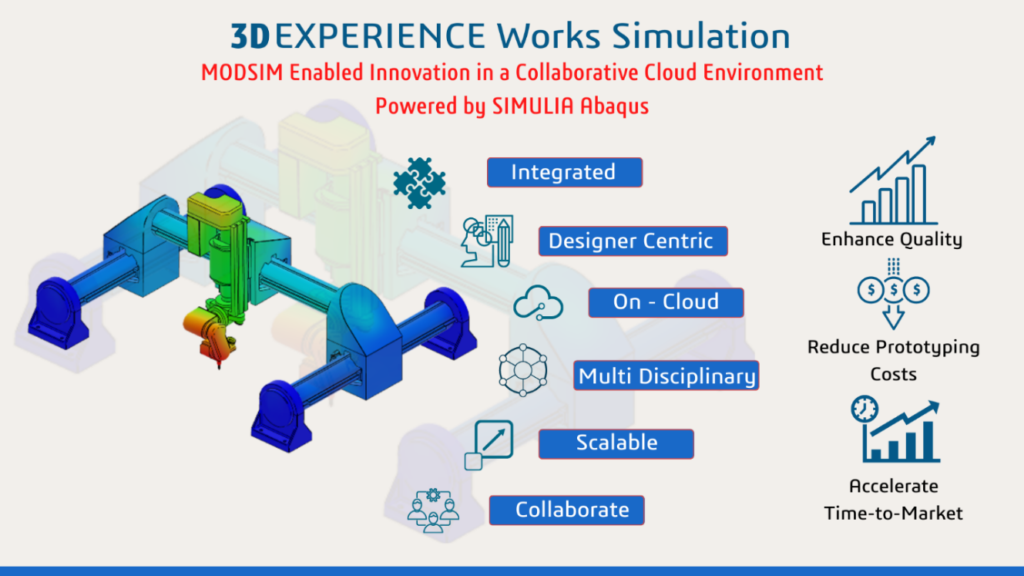

To accomplish this, engineers need to have access to different tools to perform different simulations in a unified environment. Simply put, the 3DEXPEREINCE Platform provides access to multidisciplinary tools to perform different simulation across different physics while maintaining associativity with initial CAD data.

3DEXPERIENCE MODSIM Drives Faster Innovation

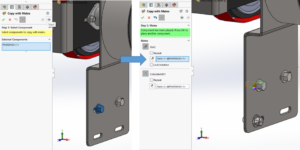

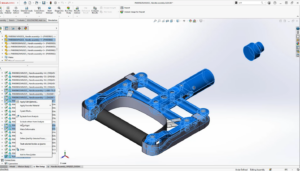

The backbone of this MODSIM strategy is the 3DEXPERIENCE platform. It offers users a unified experience that can be optimized to their given industry, role and expertise. This integrated environment is designed to improve communications between various multidisciplinary tools that is used throughout a product’s lifecycle (from CAD to CAE, test, production and more). Instead of transferring and converting models from one tool to another, MODSIM technologies work on one model, offering a single source of truth for everyone working on the design.

The 3DEPXERIENCE Platform provides access to different simulation tools for designers, engineers and analysts such as

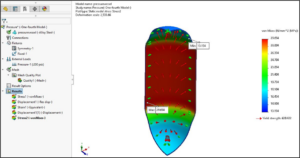

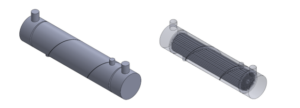

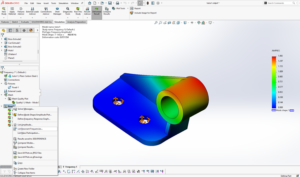

- Abaqus: for linear and non-linear structural simulations

- Fe-safe: for durability analysis and life cycle estimations

- CST Studio Suite: for high and low-frequency electromagnetics calculations

- Tosca: for shape and topology optimizations

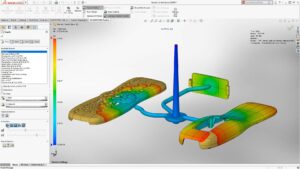

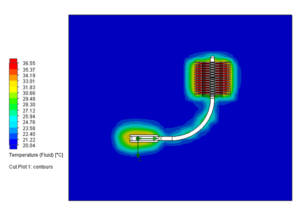

- XFlow: for Lattice-Boltzmann CFD simulations

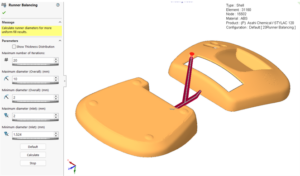

- Plastics: for plastics injection molding simulation and many more from SIMULIA brand under Dassault Systemes.

It is these multidisciplinary workflows that connect the 3DEXPERIENCE’s vast simulation options to the MODSIM philosophy. The potential to execute some of these multidisciplinary workflows, the platform is the place where with a single data model and a single user interface.

Embracing MODSIM allows you to

- Experience all aspects of your design by predicting a product’s behavior much earlier removing the expense of physical prototyping

- Explore more design alternatives, allowing you to optimize the design to best meet functional requirements and manufacturing constraints

- Finally, accelerate collaborative innovation across dispersed teams who all work on the same data in real time

To summarize, Modelling and Simulation are not new to the manufacturers across the industries, where design engineers and analysts working in silos. This leads to longer product development cycle. However, now they can work in the environment where it has best integration of both the main elements of product development i.e modelling and simulation and can experience best benefits from the 3DEXPEREINCE Platform.