In multi-cavity injection molding, runner balancing plays a very critical role in ensuring uniform filling across all cavities. If runners are not properly balanced, some cavities generally fill faster than the others, leading to inconsistencies in the quality, scrap and production inefficiencies. So, achieving perfect runner balancing is key. To achieve the same, proper runner design, gate placement and flow analysis play a vital role in ensuring the uniform fill across all cavities. In this blog, we will explore the basics of Runner Balancing in Multi-Cavity Molds, why it is crucial to achieve optimal mold performance, and how we can benefit from SOLIDWORKS Plastics Simulation.

Benefits of Runner Balancing:

- Optimizes fill time by ensuring multiple cavities are filled at the same time

- Helps in uniform shrinkage of components, so it matches the component’s fit & finish.

How to carry out Runner Balancing for existing runners in Multi-Cavity Study:

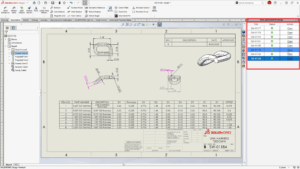

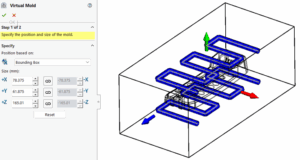

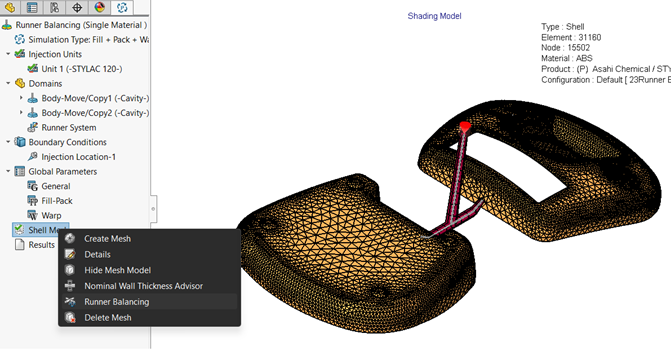

Once we have created the cold/hot runner in our plastics simulation study and meshed the component, we have the Runner Balancing option under Mesh options.

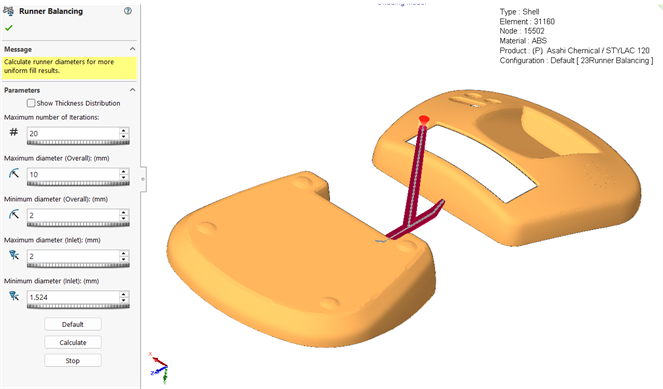

The runner balancing automatically finds the best balance for the runner diameters to have an equal flow in each cavity. Under the Runner Balancing dialog box, we can input the parameters, such as the maximum number of iterations to be carried out. & min. Diameter (overall and inlets). Based on these parameters, the solver finds a suitable runner design. If you entered custom values & want to return to default values, you can check the default option.

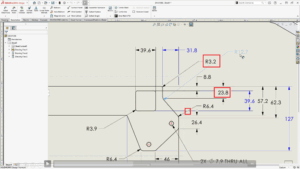

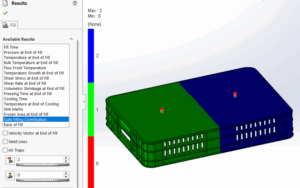

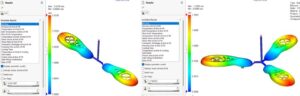

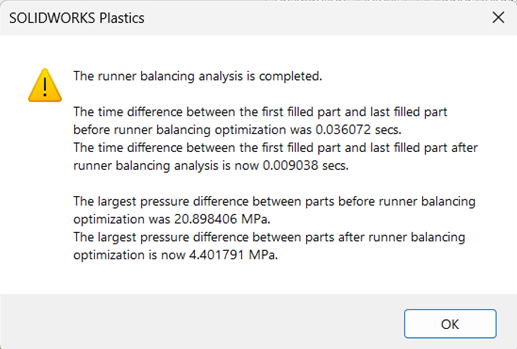

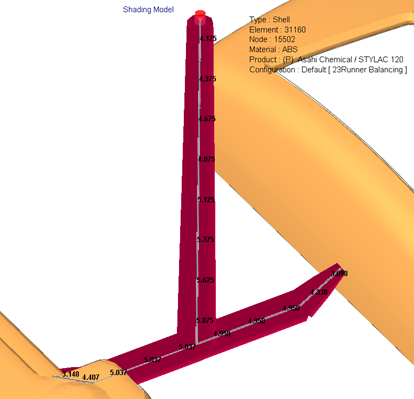

Once the analysis is done, we will see the results summary; we can observe the fill time & pressure difference of the first & last filled components in the multi-cavity.

The diameters of the runners and gate, which have changed to balance the flow, can be viewed using the Show Thickness distribution in the Runner Balancing dialog box.

So, we have seen how runner balancing is critical in multi-cavity mold design and impacts the plastic injection molding process. It is essential to use and master the runner balancing since it’s one of the pre-processing steps in SOLIDWORKS Plastics Simulation.

We will continue to see the other advanced options in coming blogs, which will be helpful for you while working in SOLIDWORKS Plastics.

If you want to know more about this or want to see the potential of SOLIDWORKS Plastics, which can improve the Design to Manufacture process in your day-to-day activity, do contact us through [email protected]

Author Details:

Ramesh Aravind is a Customer Success Associate based out of Chennai, Tamil Nadu. He has completed Master’s in Engineering with specialization in Industrial Metallurgy. He had joined Conceptia Konnect team in August, 2022 and has a good experience in SOLIDWORKS, Simulation & 3DEXPERIENCE Works solutions.