ISIGHT

Process Automation and Design Exploration

Automate Design Exploration And Optimization

Isight provides designers, engineers, and researchers with an open system for integrating design and simulation models—created with various CAD, CAE, and other software applications—to automate the execution of hundreds or thousands of simulations. Isight allows users to save time and improve their products by optimizing them against performance or cost metrics through statistical methods, such as Design of Experiments (DOE) or Design for Six Sigma.

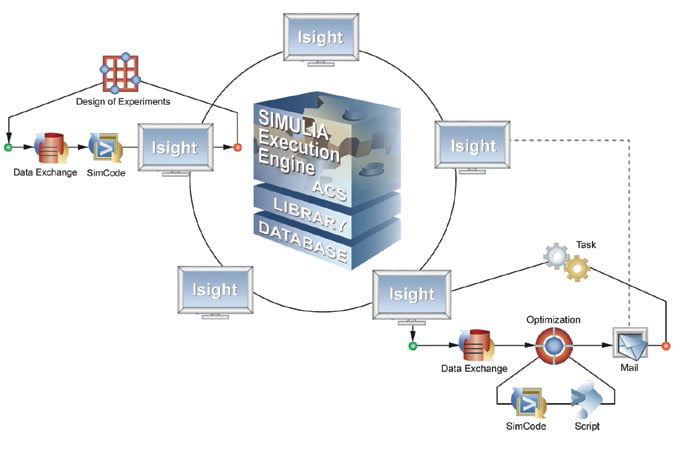

Isight combines cross-disciplinary models and applications together in a simulation process flow, automates their execution, explores the resulting design space, and identifies the optimal design parameters based on required constraints.

Isight’s ability to manipulate and map parametric data between process steps and automate multiple simulations greatly improves efficiency, reduces manual errors, and accelerates the evaluation of product design alternatives.

Isight combines cross-disciplinary models and applications together in a simulation process flow, automates their execution, explores the resulting design space, and identifies the optimal design parameters based on required constraints.

Isight’s ability to manipulate and map parametric data between process steps and automate multiple simulations greatly improves efficiency, reduces manual errors, and accelerates the evaluation of product design alternatives.

Simulation Process Flows

The intuitive Design Gateway graphical user interface enables users to quickly create integrated simulation process flows, which couple simulation programs regardless of discipline, programming language, or format.

Isight provides drag-and-drop process flow creation, parameter mapping, and problem formulation.

Isight provides drag-and-drop process flow creation, parameter mapping, and problem formulation.

Execution, Results Visualization, and Post processing

The Runtime Gateway enables desktop and distributed execution of engineering process flows. It also enables the creation of graphs and tables to visualize results.

ISIGHT OFFERS AN EXTENSIVE LIBRARY OF PARALLEL PROCESS COMPONENTS TO ENABLE ENGINEERS TO THOROUGHLY AND QUICKLY EXPLORE THE DESIGN SPACE

Design of Experiments

The DOE component enables engineers to quickly assess the impact of various design variables based on a set of objectives and identify significant interactions. The design data produced by DOE runs can also be used with approximation models for use with optimization methods.

Quality Methods

Isight provides stochastic methods that account for variation in product designs and their operating environment. The Monte Carlo Simulation (MCS) component offers an accurate method to address uncertainty and randomness in the design process. It allows users to sample the design space, assess the impact of known uncertainties in input variables on the system responses, and characterize the statistical nature (mean, variance, range, distribution, etc.) of the responses of interest.

Optimization

Isight provides a comprehensive selection of parallelized optimization techniques that can be applied to a variety of problems. It also includes techniques that can handle multi-objective optimization problems.

Approximations and the Visual Design Driver

Isight offers powerful real-time tools to interpolate results of computationally intensive realistic simulations. Approximation models are automatically cross-validated to ensure accurate predictions. The Visual Design Driver allows users to see their approximation models from many different views and “surf” the design space graphically and interactively.

Data Matching

This process enables simulation models to be calibrated by minimizing any variety of different error measures using optimization techniques. Target data can be imported as experimental or simulation results.

ISIGHT Benefits

- Drastically reduce design cycle time through integrating workflow processes in an automated environment.

- Deliver more reliable, better-quality products through accelerated evaluation of design alternatives.

- Lower hardware investments through effective use of legacy systems and more efficient job distribution.

- Eliminate the bottlenecks of ineffective communication by enabling secure design collaboration among partners.