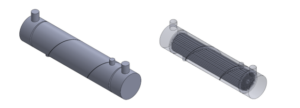

In life there are many things that we do by inertia, because all our life has been done this way or because we do not even consider that things can be changed. Throughout our history this has been something usual that has accompanied us on many occasions. One of the most notorious cases is the size of the auxiliary fuel tanks of the space shuttle.

The diameter of these deposits is 1.4351 meters … Why this measure so rare?

Someone may think that it is because, in reality, it was not done in a metric system.

Perfect, let’s see then:

1.4351 meters = 4 feet and 8.5 inches

Well, it is not a very rounded measure, let’s say. The truth is that it is a problem that we have been dragging for a long time. Let’s see the real story:

The company that manufactures these deposits for NASA is Thiokol and is located in Utah. Once manufactured, they must be transported to their launch site in Cape Canaveral, transported by train and through the Rocky Mountains. Therefore, from the outset, the size is conditioned by the width of the tunnels … and what determines the width of the tunnels?

The width of the train.

And what determines the width of the train?

The track width. The distance between rails in the USA is 4 feet and 8.5 inches.

And what determines the width of the road in the USA?

The US railways were built by English settlers, using the same track width as in England.

And what conditioned the gauge of the English railways?

Because the railroad builders in England were the ones who built the English trams, therefore, it was the width of the tramline that determined the width of the railway line.

And what conditioned the axle width of the trams?

Streetcar builders used the same tools and methods that were used to build carts, in fact, the tram started as a horse-drawn carriage on rails.

Let’s continue,

What determines the width of axles of a cart?

The roads of England and of all Europe are marked by grooves made by the ruts of the cars, a width between wheels different from the width of these grooves would have been catastrophic for any car and would have ended by splitting the axle or the wheels.

So, who made those 4-foot and 8.5-inch grooves?

Well, those grooves had been recorded in Europe since the time of the Romans. Therefore, it was the

Roman cars that had that width between wheels.

But why was the wheel width of a Roman car 4 feet and 8.5 inches?

Well here, finally, a logical explanation:

The war chariots of the Roman legions were pulled by horses (usually two), so that the horses did not bother each other had to have a certain separation. In turn, the wheels of the cars should not pass through the footprints of horses to not destabilize and at the same time not be too wide to allow cars in the opposite direction of the road. This translated into the magical measure of 4 feet and 8.5 inches.

Therefore, the measurement of one of the most advanced means of transport on the planet depends on the “rear of the horse”, one of the oldest means of transport on the planet.

These acquired habits, if we transfer them to the business world, much cost, time and money can saved that we are not aware of.

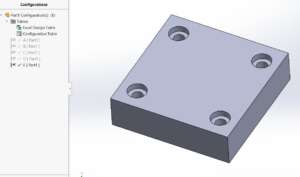

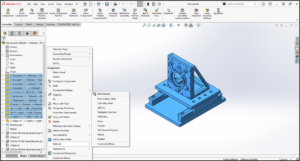

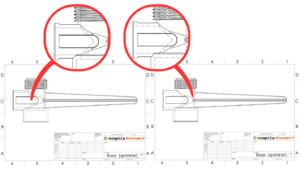

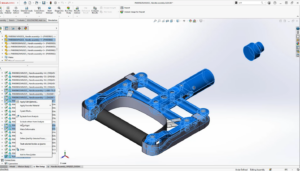

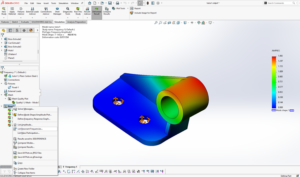

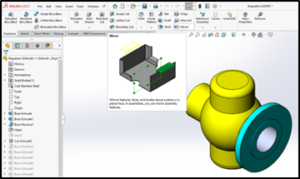

In the world of engineering and manufacturing, one of these habits is the creation of 2D drawings.

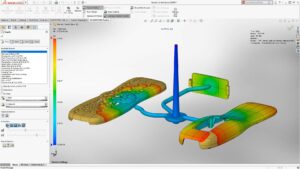

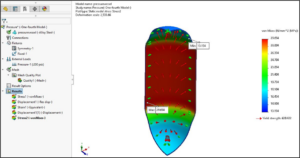

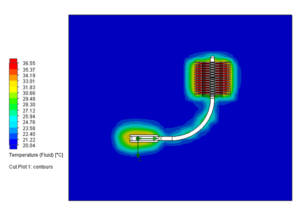

Today, most companies have 3D design tools and there are many workshops that have CAM machining systems capable of importing and opening the main 3D file exchange formats (STEP, IGES, Parasolid, STL, etc.) Still, it never ceases to amaze me the amount of hours that engineers and designers invest creating documentation and 2D drawings for their own workshop or ancillary workshops. It is even more surprising when the engineers and designers themselves recognize that it is one of the things that most demotivates them. In addition, in the process of mental translation from 2D to 3D it is more likely that there are errors or part of the information is lost.

In a 3D world (4D if we count time ), in which we think and see things in 3D, in which we devise and invent in 3D and manufacture what was devised in 3D, why do we pass information to each other in 2D?

It would be like recording a film in 4K and surround sound and projecting it in black and white and silent movies. And when we asked the cinema, why did you project it like that (black and white and silent movies)?

The answer, surely it would be: Because since cinema was invented, it has always been done that way.

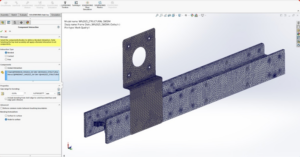

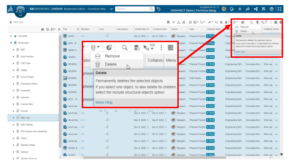

Changing all the transport infrastructures of a country is expensive and probably unfeasible. However, most companies are already prepared or need very little investment to make a qualitative leap in their production processes and make the most of the opportunities that 3D gives us and the functions of Model Base Definition (Information Based on the 3D Model).

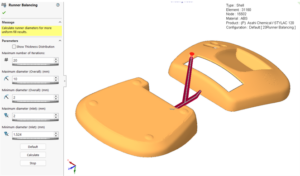

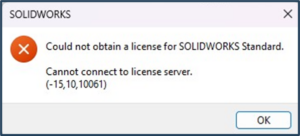

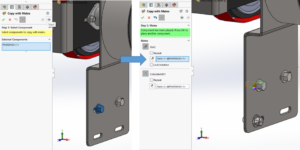

In short, nowadays, with SOLIDWORKS MBD we can make 3D pdf drawings so as not to lose part of the information in the communication process between departments.

Application Engineer,

Sanjay Maddila