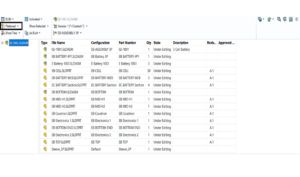

In the realm of engineering and design, efficient management of data is paramount. For businesses leveraging SOLIDWORKS PDM (Product Data Management), the choice between a single workflow or multiple workflows can significantly impact productivity, collaboration, and compliance. While a single workflow may seem like a streamlined approach, its limitations become apparent as organizations grow in complexity and scale.

Before we discuss workflows in Data Management (SOLIDWORKS PDM Professional), let me introduce you to Product Data Management.

What is PDM ( Product Data Management)

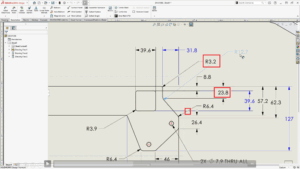

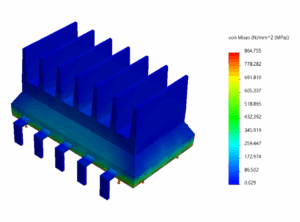

Product Data Management (PDM) is a system used to manage and control all data related to a particular product throughout its lifecycle. This includes various types of information such as design data, engineering specifications, manufacturing instructions, technical documentation, bills of materials (BOM), and any other relevant data.

Limitations of Managing Single Process (Work) Flow Process

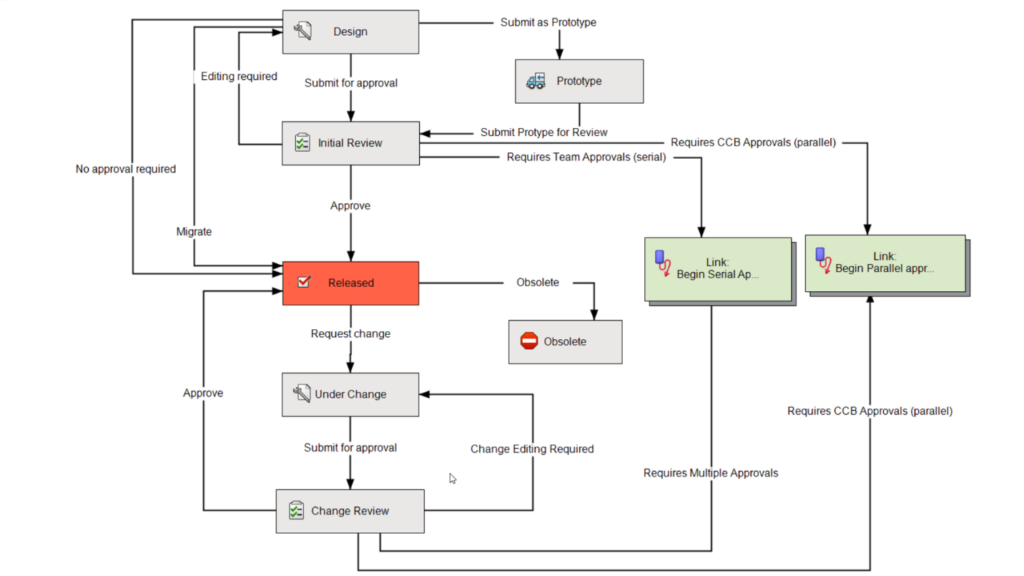

Even though it may seem simple, a single workflow might provide several difficulties. Its lack of adaptability frequently makes it unable to meet the various requirements of various projects or document types. Think about how intricate a product development cycle may be; several approval procedures or lifecycle stages might be needed for parts, assemblies, and drawings. Trying to fit every document into a single procedure might result in risks to compliance, inefficiencies, and bottlenecks.

Furthermore, visibility and control may be hampered by the rigidity of a single procedure. It may be necessary for stakeholders to have detailed information about the status of document types or projects, which a monolithic workflow finds difficult to deliver. An additional layer of complexity arises in regulated businesses from compliance. A one-size-fits-all strategy may not satisfy the strict regulatory standards, putting companies at risk of fines and compliance issues.

Unlocking Efficiency with Multiple Workflows

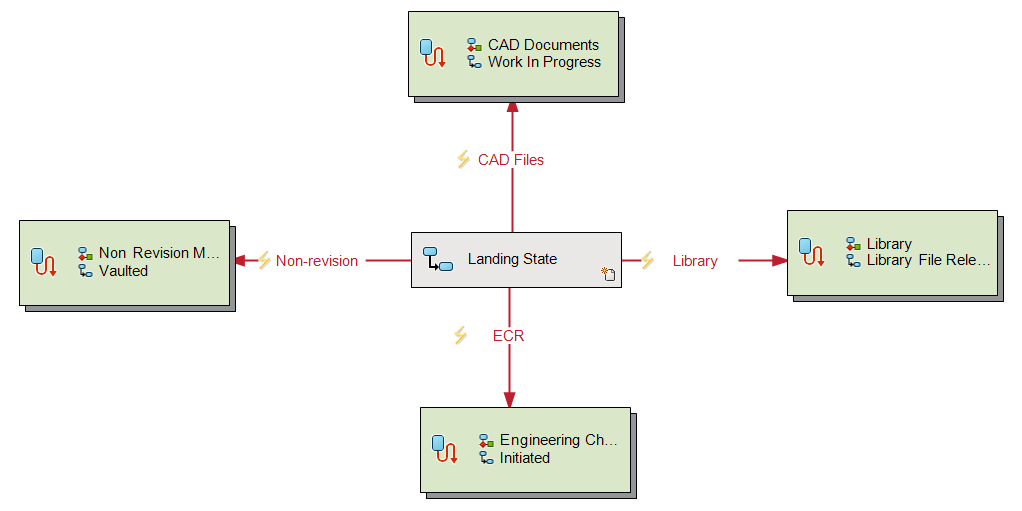

Various processes designed to meet the requirements of projects, product lines, and document kinds. Using SOLIDWORKS PDM with a multi-workflow approach can help organizations reap several advantages.

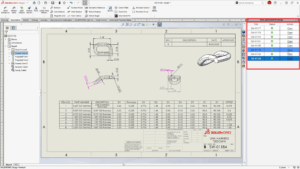

Above all else, adaptability is paramount. Businesses can create approval processes that properly match the complexities of their projects and products with the help of several workflows. Every sort of document, from straightforward part updates to intricate assembly approvals, has a workflow that is customized to meet its unique needs. This customization expedites the design process and lessens confusion and errors.

Furthermore, scaling becomes possible. It becomes easy to add new phases, transitions, or document kinds as an organization grows or changes. Businesses can design new workflows that are suited to changing requirements rather than retrofitting an existing procedure to handle change. Because of its scalability, SOLIDWORKS PDM can expand with your company and adapt to changing market trends without losing its effectiveness as a design data management solution.

Optimizing Collaboration and Compliance

Multiple workflows are necessary for effective collaboration and compliance. By granting stakeholders unambiguous access to document progress, companies can improve cooperation among teams, departments, and even outside partners. Everyone is kept informed through notifications and alerts, which help to keep projects on schedule and meet deadlines.

Furthermore, compliance becomes more straightforward. Businesses can precisely enforce regulatory standards by utilizing multiple procedures. Every workflow may be customized to guarantee compliance at every point of the document lifecycle, whether that means following industry standards, going through specific review procedures, or keeping audit trails.

SOLIDWORKS PDM Professional for Multiple Workflows

A meticulous approach is necessary for effective design data management. A single workflow could be straightforward, but it has drawbacks that might impede compliance, productivity, and teamwork. Organizations can customize approval procedures to meet their specific needs, grow with ease, and maintain regulatory compliance by embracing different workflows within SOLIDWORKS PDM Professional.

Effectiveness, cooperation, and adherence to rules are essential components of a good design management system. Businesses may fully utilize SOLIDWORKS PDM Professional with numerous workflows, enabling teams to develop, work together, and prosper in the current fast-paced engineering environment.