In my previous blog, “What’s New SOLIDWORKS Simulation 2025 New Enhancements – Part 1,” I covered the new enhancements to SOLIDWORKS Simulation 2025 that provide major benefits. Let us see the remaining enhancements in SOLIDWORKS 2025 with respect to Simulation in this blog.

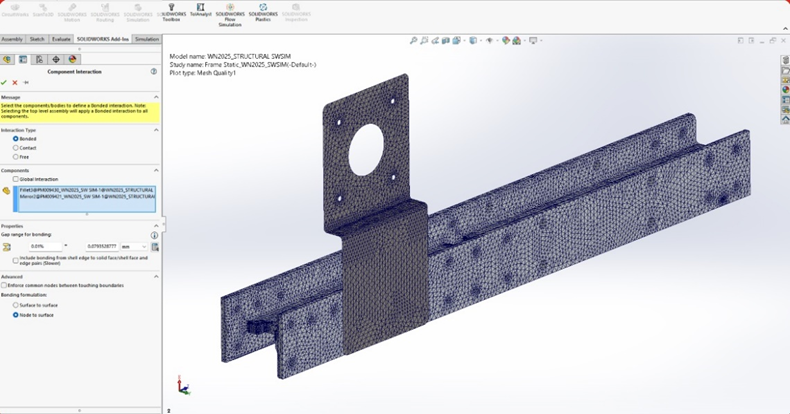

Mesh Accuracy for Bonding Contacts:

SOLIDWORKS Simulation 2025 comes with accurate improvements in both Node-to-Surface contact and Surface-to-Surface contact Bonding formulations. Usually, in some scenarios, we must enforce the gap between structural components while using Bonded contact between them. So, we must slightly compromise on accuracy, but SOLIDWORKS Simulation 2025 comes with improved accuracy for “Node to Surface Bonding with Offset”. SOLIDWORKS Simulation algorithm will take care of Bonded contact with Node-to-Surface formulation with offset. This enhancement increases the accuracy of the bonding offset, as defined by the user-specified gap range for bonding.

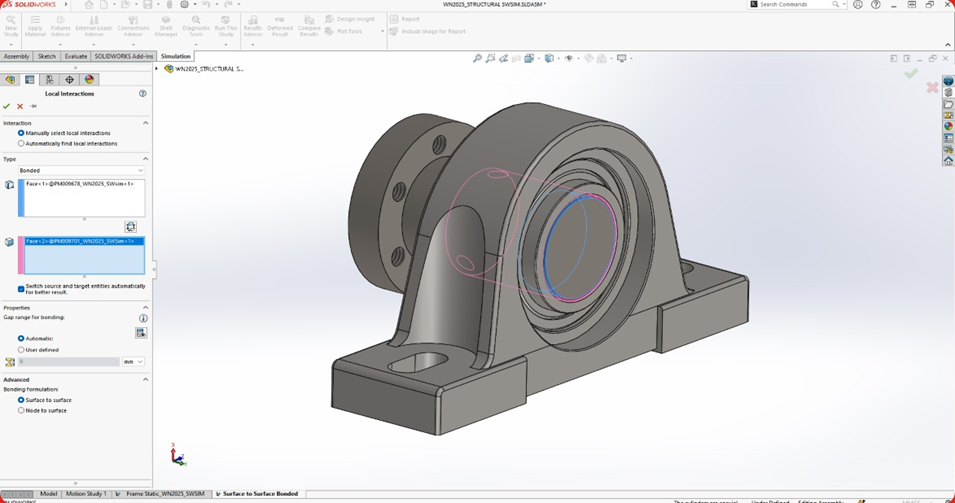

Similarly, to improve the representation of curved surfaces in cylindrical, spherical, and conical geometries, SOLIDWORKS Simulation 2025’s surface-to-surface bonding algorithm incorporates geometry correction factors. Ultimately, this enhancement avoids dense/refined mesh to capture accurate results.

Enhanced Pin Connector:

In SOLIDWORKS Simulation, Virtual Connections can reach the overall objective of analysis without sacrificing accuracy. Without modeling the actual pin shapes, we may utilize pin connections in SOLIDWORKS Simulation to mimic how pins might behave in an assembly.

SOLIDWORKS Simulation 2025 provides an enhanced Pin connector with improved performance while using a distributed coupling setup, which more accurately transfers load surfaces where the virtual pins are located. With the help of this enhancement, we can increase the overall accuracy of the Analysis.

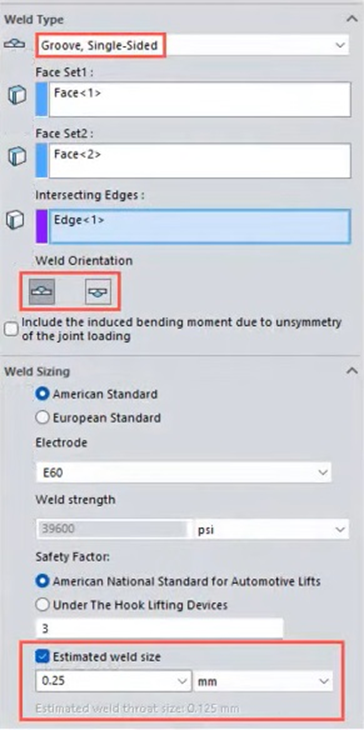

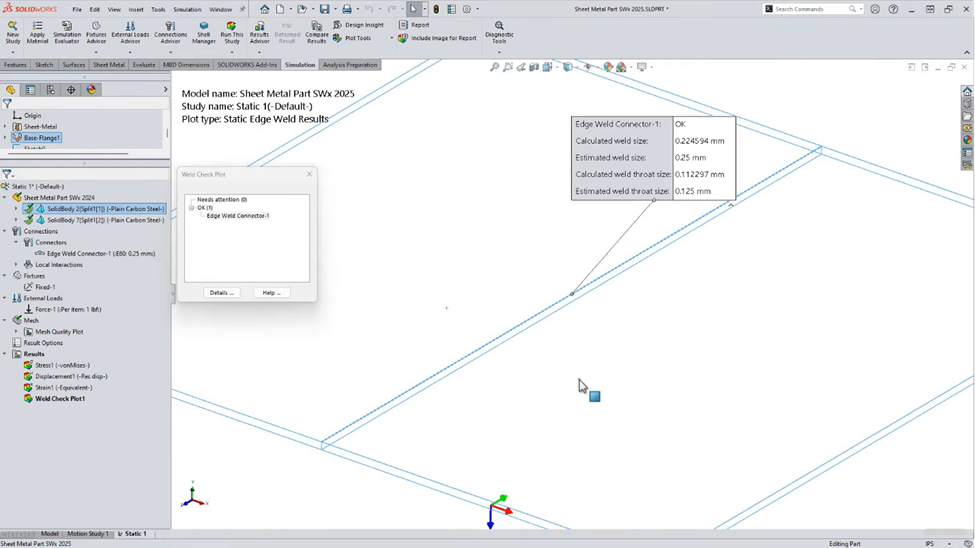

Edge Weld Connector Enhancement:

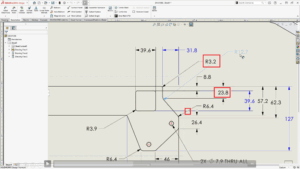

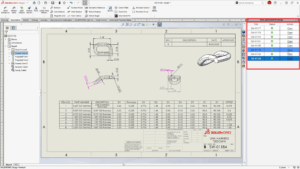

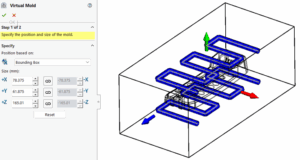

SOLIDWORKS Simulation 2025 has enhancements in Edge Weld calculations and Annotations. SOLIDWORKS Simulation automatically calculates the weld throat size based on the following formulas.

For Fillet Weld type:

Estimated weld throat size= Estimated weld size*square root (2)/2

For Groove Weld Type:

Estimated weld throat size= Estimated weld size/2 (refer the attachment)

Additionally, we can capture the Weld check plot with annotation dialogue, which lists out “Calculated weld throat size” and “Estimated weld throat size” details as attached.

Calculated weld throat size and Estimated weld throat size details help us compare and optimize inputs.

All these enhancements help us to easy to setup an analysis, improve the results of the Analysis and shorten time to market by identifying ideal design solutions fast. So, with this, we have seen the key features added in SOLIDWORKS 2025. If you wish to know more about these improvements or have an in-person session, do reach out to us through [email protected] or Request for a DEMO.