A well-crafted design refined through accuracy, foresight, and strategic planning is the foundation of any successful plastic injection molding project. However, a vital step in this process that is sometimes overlooked in haste to fulfil deadlines or save expenses is the careful assessment of designs using simulation software. In this blog, we will highlight the importance of an evaluation tool and the dangers of skipping or neglecting this important stage of the production process.

SOLIDWORKS Plastics is a product in the SOLIDWORKS Suite of Solutions that helps you simulate plastic component manufacturing more effectively. It is a desktop simulation tool integrated into SOLIDWORKS CAD, specifically focused on evaluating the design and manufacturability of plastic components for injection molding.

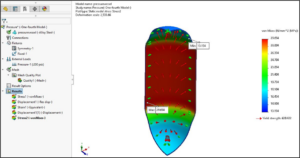

With SOLIDWORKS Plastics, you can predict the melt flow into the cavity and analyze manufacturing defects. This capability enables us to make informed decisions during the design stage, allowing for necessary adjustments to the cavity (part) and mold design.

Modelling & Simulating the components with SOLIDWORKS Plastics

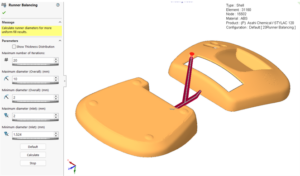

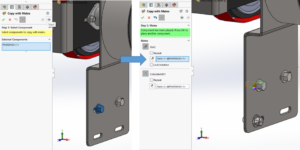

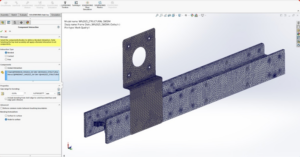

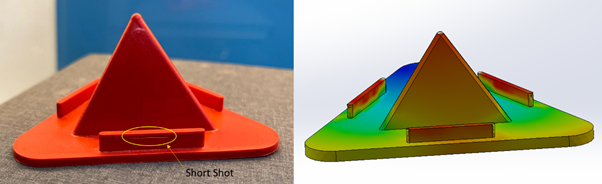

In most plastic components created using the injection molding technique, we would have seen/experienced physical defects such as excess flash, burn marks, short shots, etc. To illustrate this, we have created the exact design of the mobile phone holder (as in the image below) using SOLIDWORKS CAD. When the initial design is manufactured, we can observe the short-shot defect in the component. Plastic Injection Molding simulation has been performed for the same part with SOLIDWORKS Plastics, and we could observe a similar issue in the 3D model.

Image 1: Comparison of Mobile Phone Holder (Physical vs CAD Model)

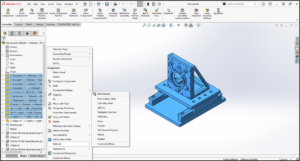

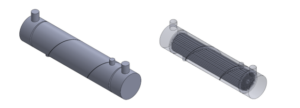

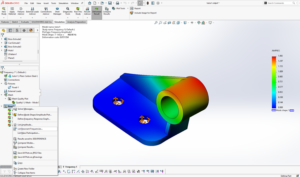

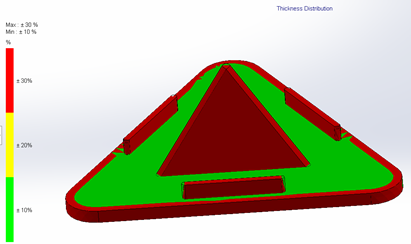

Image 2: Plot showcasing thickness distribution in the model (green to red shows thickness difference from advisable nominal thickness

Also, as per the above image, we could observe the thickness distribution across the 3D model. As an inference from this plot, the thickness difference from the advisable nominal thickness is indicated, providing us the pathway to make ideal design changes.

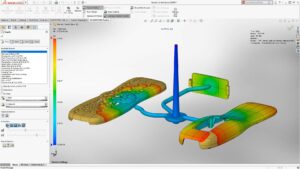

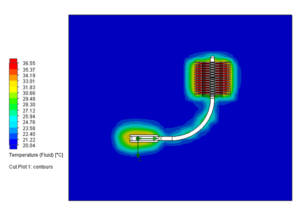

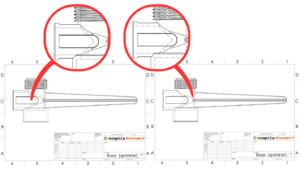

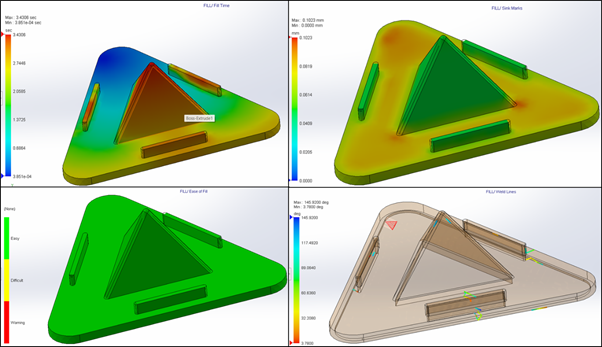

Image 3: Plots showing comparison of Time of fill, Sink marks visibility, Ease of Fill & Weld lines visibility – post Design changes in component

To overcome these manufacturing defects, we tried to imply the changes in CAD during design (with respect to the triangular cross-section) and then simulated the component. After adopting the changes, we could easily fill the mold cavity without a short-shot defect. Also, we can evaluate the formation of other defects such as sink marks (less than 80 micron) & weld lines in the component. These among other manufacturing defects could be avoided during your design phase with Simulation driven Design approach.

Capabilities of SOLIDWORKS Plastics

- Integration in SOLIDWORKS – It is completely integrated with SOLIDWORKS CAD application and you can quickly make design changes based on the simulation study results.

- Simulate the flow analysis of molten plastic into the mold cavity such as Fill, Pack & Cool stages, by which we can predict the defects at the virtual environment without actual prototyping.

- Apart from optimizing mold cavity design, we can easily create and optimize the design of virtual sprue, runners, cooling systems, and molds in SOLIDWORKS Plastics.

- The advanced capabilities include part-insert over-molding, gas or water-assisted injection molding, fiber orientation analysis, co-injection molding, and so on, which supports designers and engineers in the New Product Development (NPD) process.

Advantages of employing SOLIDWORKS Plastics Simulation in your Product Development Cycle

- Reduce time, cost, and effort involved in the injection molding prototype stages. With SOLIDWORKS Plastics, we can assess designs, predict plastic melt flow into molds, identify manufacturing defects, design molds with proper runners and cooling systems, and more.

- Improve the manufacturing process. We can fine-tune process parameters involved in injection molding, such as injection pressure, packing pressure, cooling time, and mold temperature, to achieve faster cycle times and higher production efficiency.

- SOLIDWORKS Plastics provides visual insights into the injection molding process, making it easier for engineers to communicate and collaborate with other stakeholders, such as toolmakers and manufacturing teams.

- Optimized Material Selection: SOLIDWORKS Plastics Simulation enables engineers to evaluate different materials for their plastic components. By analyzing how each material will flow, cool, and shrink during molding, engineers can make informed decisions to select the most suitable material for their application, ensuring optimal part performance.

- Reduce iterations between plastic designers and manufacturers in stablishing optimum parameters for plastic part manufacturing.

To summarize, the SOLIDWORKS Plastics solution helps us detect defects at an early stage and optimize component design, saving not only cost but also time involved in prototyping and design modifications.

Please review the link (SOLIDWORKS Plastics—Injection Mold Simulation Software (ckonnect.in)) to learn more about the tool, and feel free to contact us for a technical discussion about improving your current product development cycle.