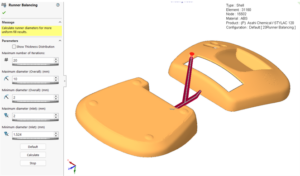

– DFM Xpress in SOLIDWORKS

– learn how to use DFM Xpress in SOLIDWORKS

– Free tools in SOLIDWORKS DFM Xpress.

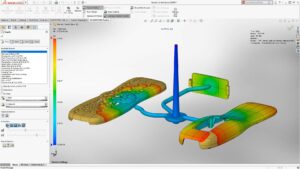

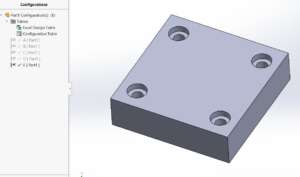

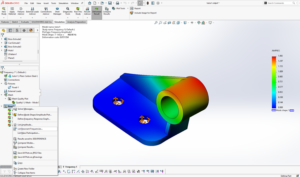

We all know that manufacturing costs can be expensive, and we are all trying to minimize costs! Simple geometry features that we create every day can be adding significant costs to your part. There are some standard tooling sizes and guide lines such as how deep you can drill a hole.

SOLIDWORKS has a free tool that will help analyze your model to identify these types of issues that may allow you to make some minor design changes that can significantly reduce your costs. Great thing is this tool is available with all three packages of SOLIDWORKS (i.e Standard, Professional and Premium).

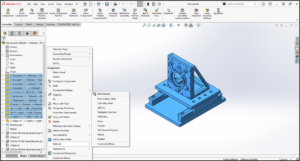

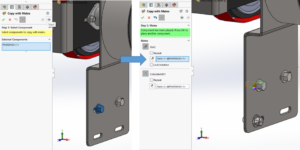

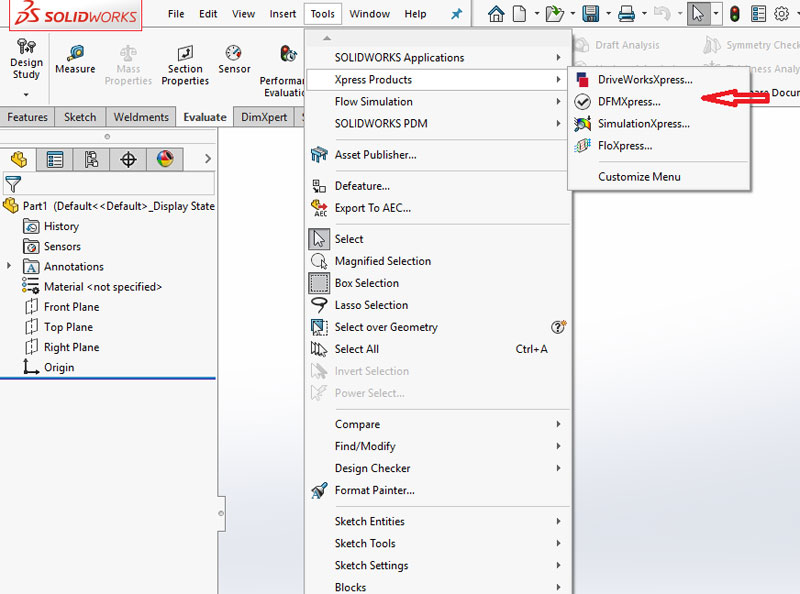

Where to Find:

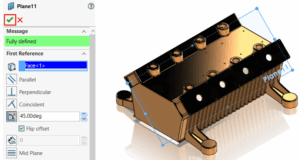

- Go to Tools > Xpress Products > DFM Xpress.

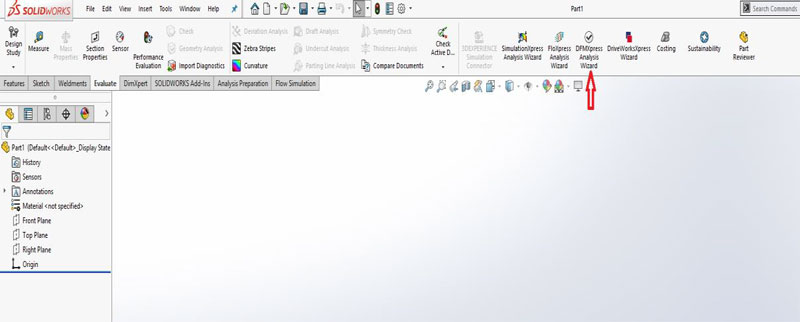

- You can find it in the Evaluate Tab in the command manager.

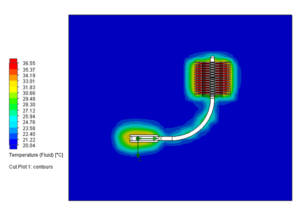

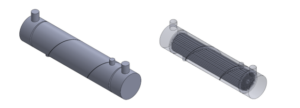

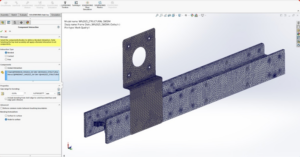

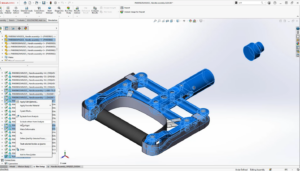

DFMXpress features include explanations and recommendations that help designers identify and rectify manufacturing feasibility issues; a basic set of rules for sheet metal, drilling, milling, turning; configurable rules parameters; and integrated and a designer-centric graphical user interface.

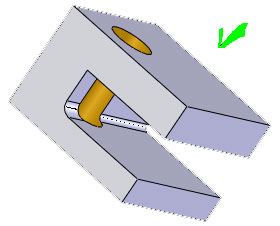

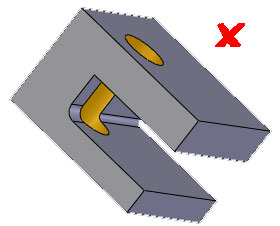

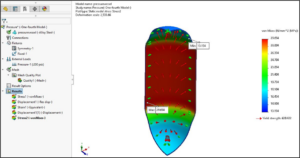

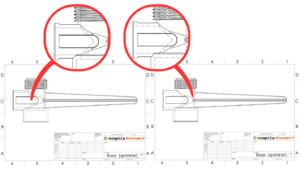

- Drilled holes should not intersect cavities. During machining, drills follow the path of least resistance when intersecting a cavity. The drill might wander when it reenters the material. If a hole must intersect a cavity, the drill axis should be outside the cavity.

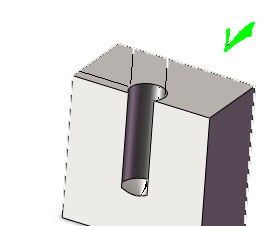

- Holes with small diameters (less than 3.0 mm) or high depth-to-diameter ratios (greater than 2.75) are difficult to machine and are not recommended for convenient mass production. Deeper holes also make chip removal more difficult if the hole is blind. To configure this rule, set Hole Depth to Diameter Ratio.

Example: Drill Rules