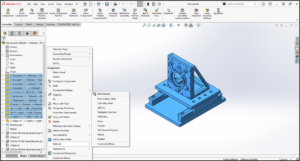

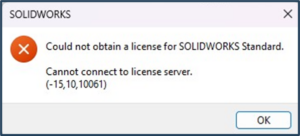

Back then, we designed products on desktops and laptops using software native to the system. It demands a system with a specific configuration. To use the tool, you must be a fully qualified Design Engineer.

We all know that to meet new difficulties, we must adapt to new technology. As time goes by, designers are expected to increasingly complete tasks more quickly, effectively, and with less hassle than before.

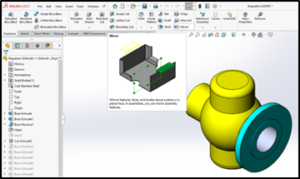

The 3D SheetMetal Maker is an easy-to-use browser-based program that provides associative parametric sheet metal design tools for creating parts, assemblies, and enclosures. Its specialized, all-in-one 3D sheet metal design environment makes it easier to streamline the creation, storage, sharing, validation, and management of designs so that you may release sheet metal components to the market quickly. Based on the 3DEXPERIENCE Works cloud platform, 3D SheetMetal Maker integrates seamlessly with the platform’s portfolios from design to manufacturing, and data management, with collaboration tools. Design data is securely stored in one central area.

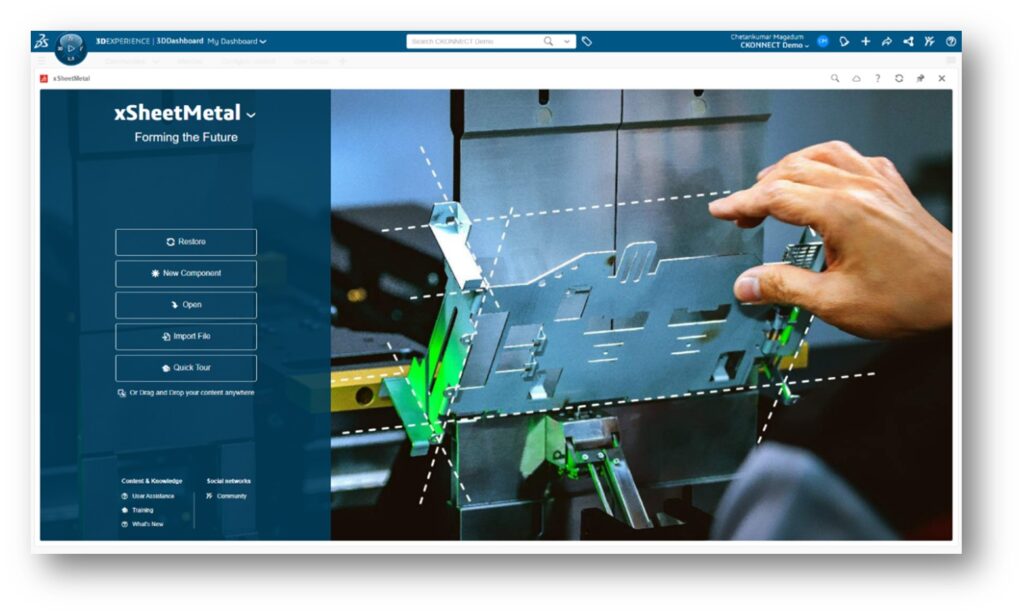

Get a glimpse of xSheetMetal and get ready to test drive 3DEXPERIENCE X-apps yourself. 3D SheetMetal Creator provides a focused experience tailored to the needs of sheet metal designers and engineers.

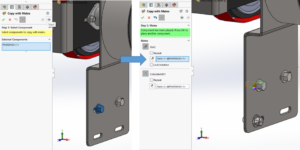

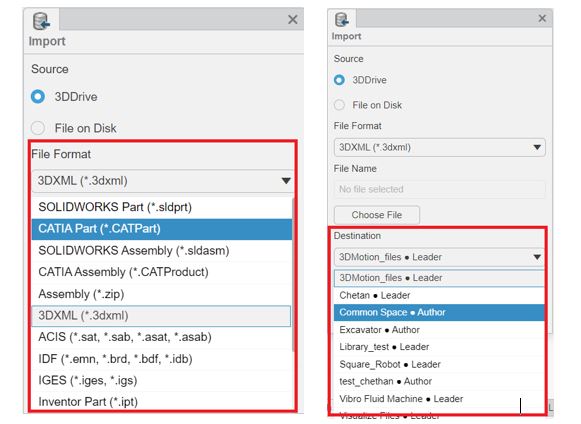

- Create a New Component with a new interface design and choose your file destination and Start Designing.

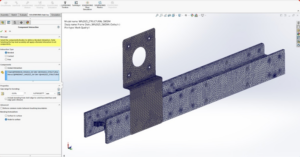

2. Importing Cad Files: With Xapps, you may begin working on your existing CAD files immediately by importing them as Neutral Files, where you can add new features to the old CAD file and delete and recreate components. Moreover, select the file destination following your project.

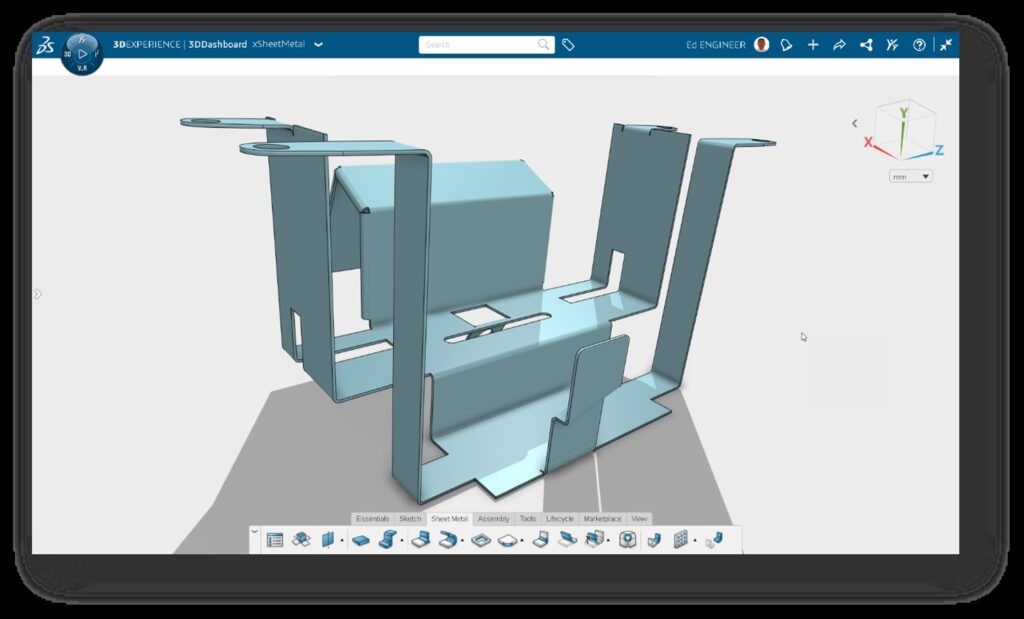

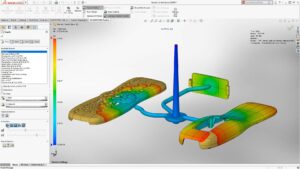

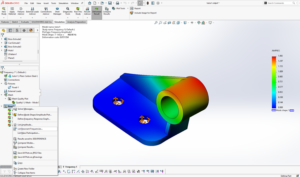

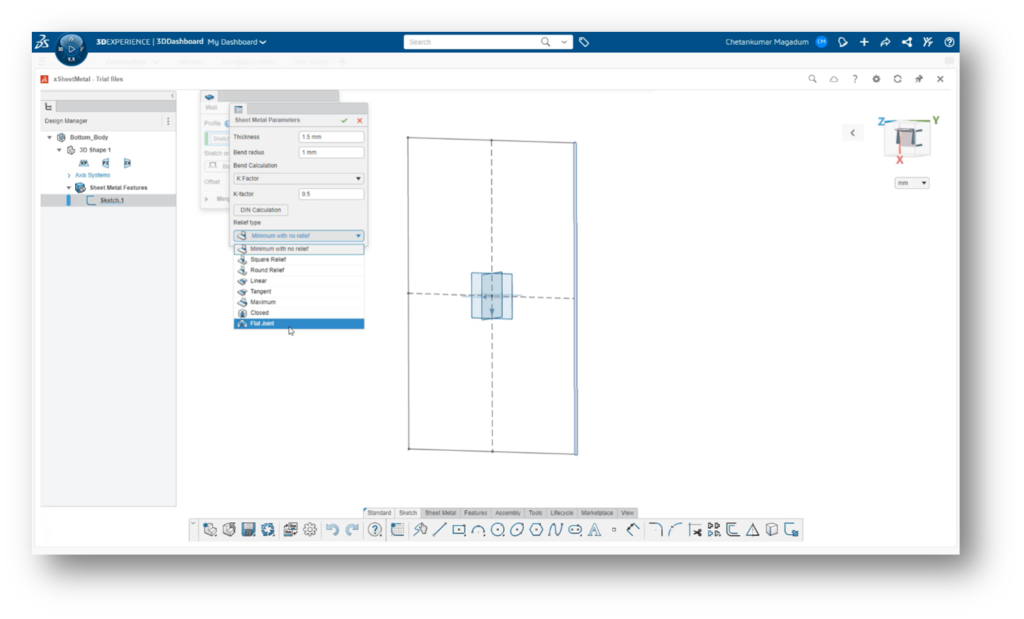

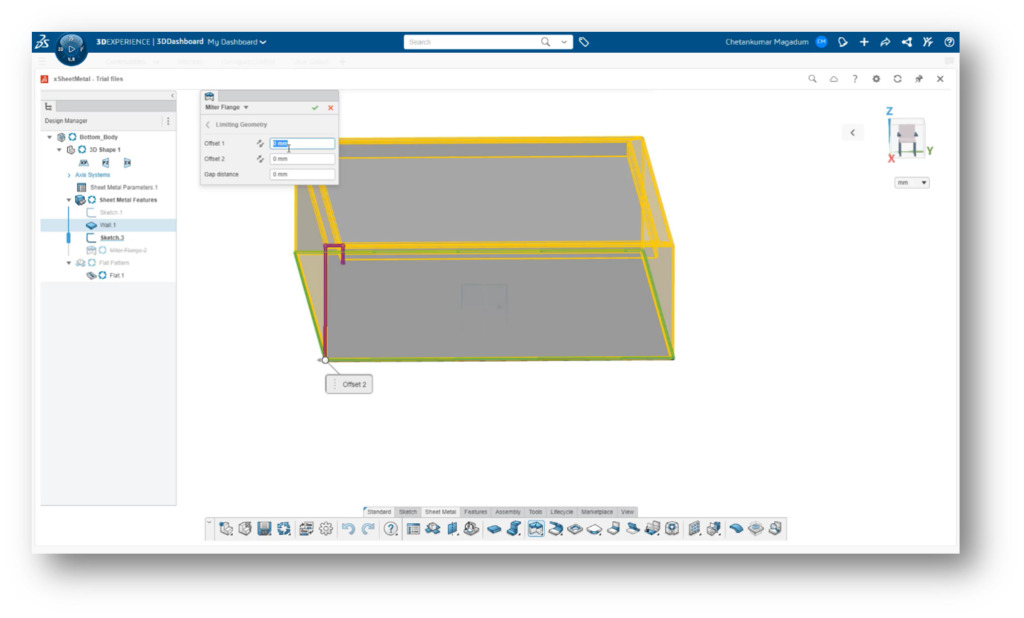

3. Making Sheet Metal: Start your design in Simple Sketch, and then use the sheet metal function to start constructing Miter flanges, edge flanges, hem bends, and other shapes. Choose the Relief type and determine the K factor using sheet metal parameters.

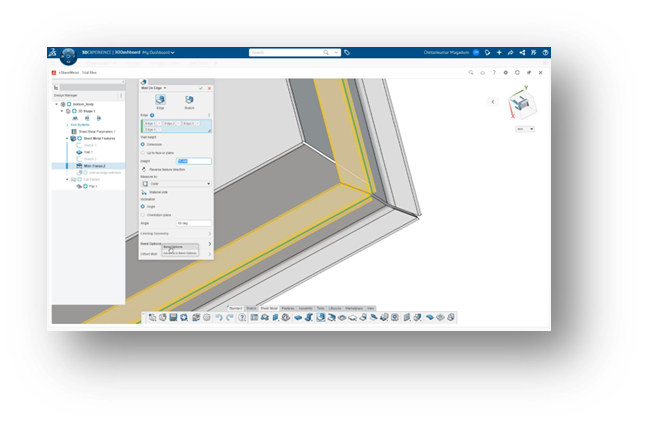

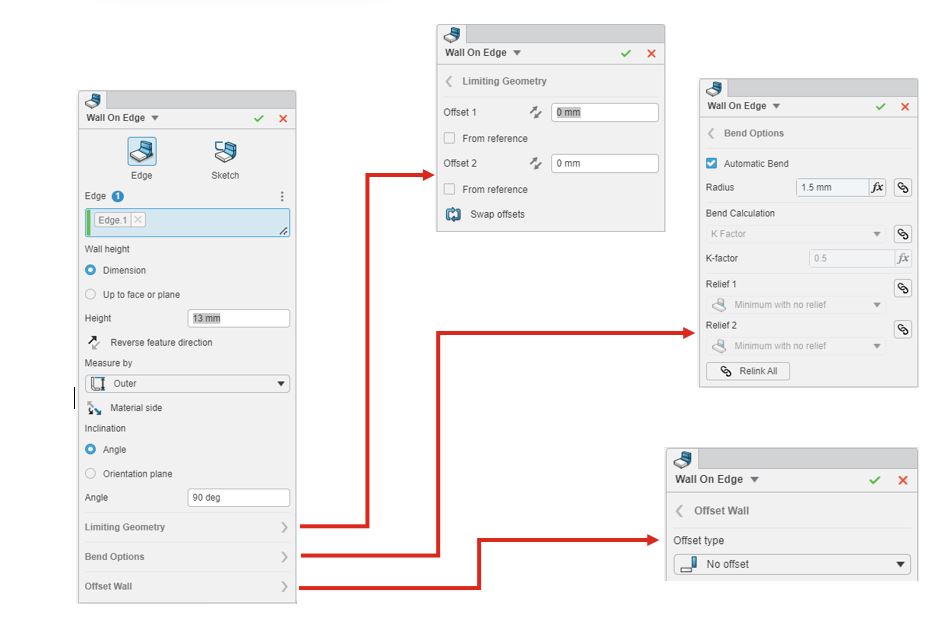

4.Creating wall on Edges: This will allow you to create flanges at the edges, with more capabilities like modifying the geometry, offset for the wall, Bend option, and more. If you want to modify the flanges with this option, you can modify the K factor and offset the bends from the edges. You can also edit the geometry of the flanges.

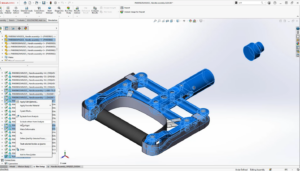

5.Insert your Gemetry: This feature lets you bring the forming tools and other standard components to the assembly. These standard components are available on the cloud.

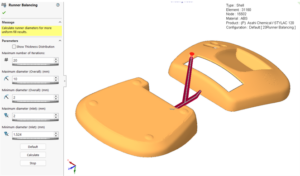

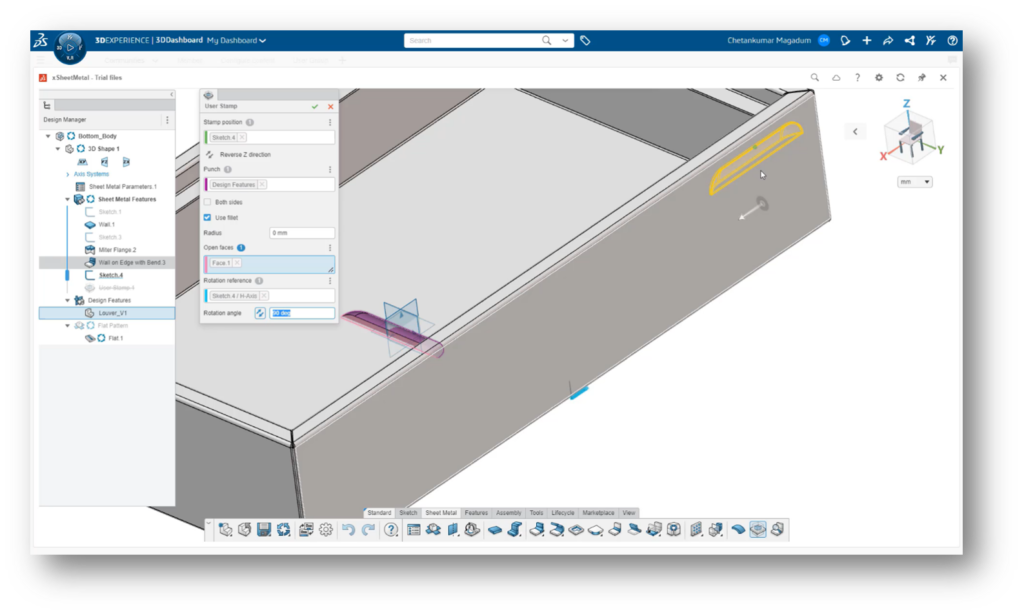

6.Stamping:

Using this feature, you can choose the face and change the placement by rotating with an angle value. Stamping is the same as forming.

Here, we’re using the louver to create a form that will be imported from the standard library created in the cloud and place a sketch that will also be able to identify the user’s face concerning the sketch and then adjust the parameters to spin (Rotate) the punch.

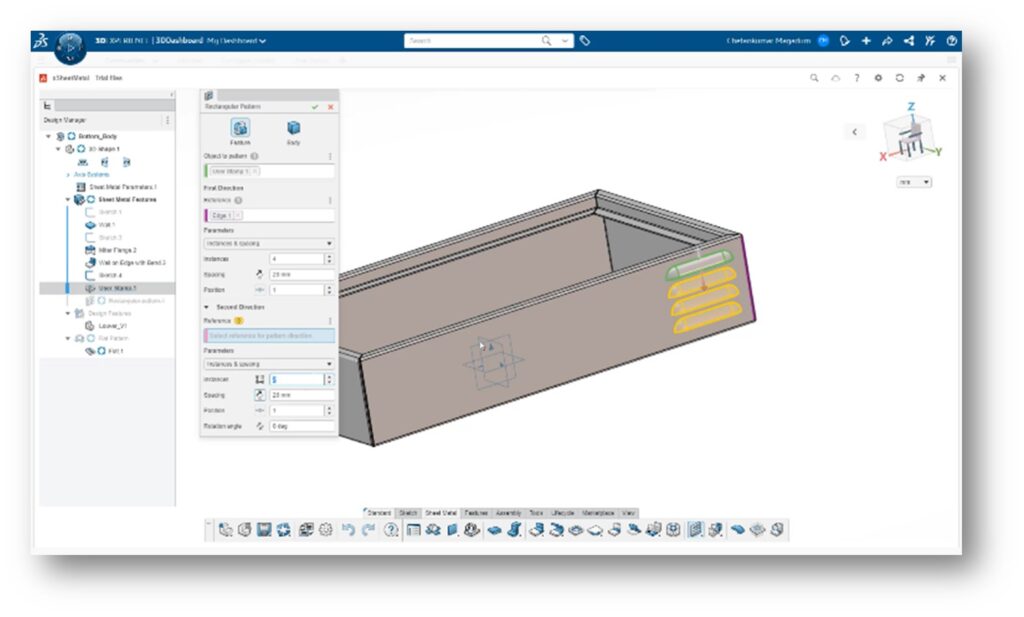

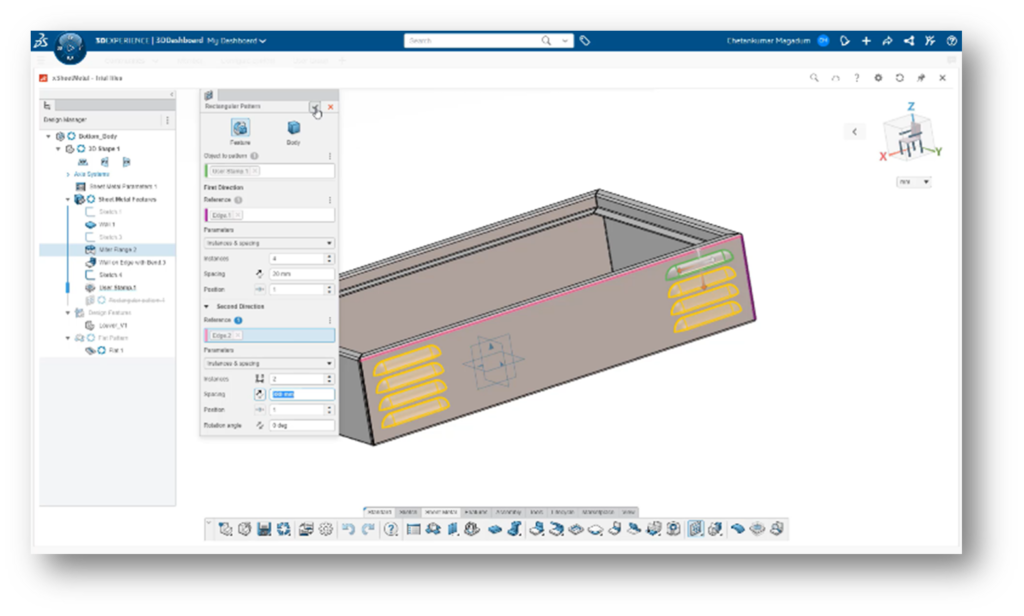

7.Create Pattern-Pattern is my favorite tool because it shortens my design time, generates patterns for Sheetmetal features like holes, forming, and any sketch, and allows us to quickly define parameters like the number of patterns. Direction, Rotation, Spacing, and Many others.

Why 3DEXPERIENCE Platform driven browser based 3D SheetMetal Creator?

1. Auto update to the latest version

2. Intuitive interfaces and controls that are easy to understand and navigate.

3. Reduce your learning curves and allows the designer to focus more on their creative Process

4. Save your Designs on the cloud with the latest revisions accessible to the rest of your team.

6. Browser-based sheet metal design

7. Single Modeling Environment

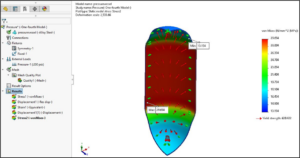

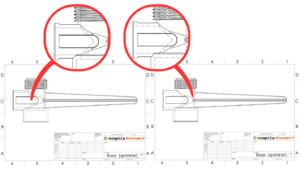

8. Verify flat patterns for design manufacturability

Build components, assemblies, and enclosures with an intuitive, browser-based solution that offers associative parametric sheet metal design capabilities. Its specialized 3D sheet metal design environment helps you streamline how you create, validate, and manage designs. Learn more about 3DSheetMetal Creator.

The 3DSheetMetal Creator Role on the 3DEXPERIENCE Platform will enable you to create the design anywhere, Anytime, and help your company develop the most profitable products.